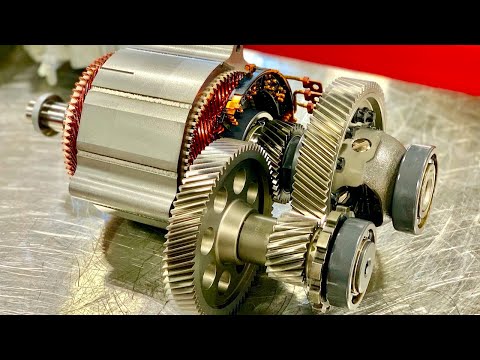

Chevrolet Bolt EV Traction Motor - Deep Dive

WeberAuto:

Hello, I'm professor John Kelly and this

is the Weber Auto YouTube channel.

In this episode we will be disassembling

the drive unit the electric motor and

gear reducer out of our 2017 Chevrolet

bolt on the hoist behind me here. now

this drive unit and electric motor

combination is is all one piece,

unlike the Nissan Leaf that has a drive

unit that unbolts from the electric

motor. This drive unit is rated at 150

kilowatts which is 201 horsepower, it is

also rated at 360 Newton meters of

torque which is roughly 266 foot-pounds

of torque.

Now let's let's talk about torque just a

little bit. That torque rating is what

the motor itself is capable of producing,

that is not the same as the torque that

ends up at the wheels of the vehicle, so

for example the Chevrolet Spark EV

produced by Chevrolet before the Bolt

here

actually had an electric motor that

produced 540 Newton meters of torque, the Bolt EV electric motor only produces

360 Newton meters of torque and so you

might be misled into thinking that the

Spark EV had more torque; well, the motor

did, but not the torque delivered to the

axles that drive the wheels. So the gear

reducer right here on the side of this

drive unit has an impact on that because

gear reduction is also torque

multiplication minus frictional losses, so

the Spark EV had a 540 Newton meter

electric motor but it only had a three

point one five to one gear reduction

unit which resulted in about 1700 Newton

meters of torque at the wheels, at the

axles. the Bolt EV electric motor

produces 360 Newton meters of torque a

whole 180 Newton meters less of torque

from the motor, but it has a seven point

zero five one eight to one gear

reduction through this gear reducer

which multiplies that 360 Newton meters

of torque by seven point zero five one

eight, which gives us over 2,500 Newton

meters of torque at the axles. So there

are other electric vehicles out there

that are being produced right now that

have higher torque higher motor torque

than the Bolt EV

but what would be interesting, I and

I don't know what their gear ratios are

yet, is to see what is the torque

actually to the axles what's the torque

to the ground because that's what you'll

feel when you step on that accelerator

pedal, that's the torque to the wheels

that makes the vehicle move. The design

of this drive unit this electric motor

it has a peak amperage draw of 400 amps

versus 450 as for the Spark EV so it

uses less current to provide more torque

so it's a more efficient better design

electric motor. The electric motor in

this drive unit spins clear up to 8810 rpm where the

Spark EV only spun up to about 4500 rpm,

and we'll take a look at some

differences in the electric motor design

and the stator winding design that

allowed it to spin at those higher rpms

without the AC losses that typically

occur at higher rpm. As mentioned in the

previous video on high voltage

components of the Chevrolet Bolt EV this

drive unit uses about 2.9 litres, around

3.1 quarts of Dexron HP fully synthetic

base transmission fluid automatic

transmission fluid. It also is cooled by

the General Motors Dexcool 50/50 mix

of coolant and deionized water. Okay

let's take a look at the outside of the

housing here of this drive unit. The

official name or designation of this

drive unit by General Motors is the

1ET25. The one means it's a one speed

trans axle, this doesn't shift, E means

it's electronically controlled, T means

it's a transaxle, and the 25 is a

relative torque rating. Alright, right

here on the front of the transmission is

the actual last eight digits of the

vehicle identification number and you

can see that MMF right there, that is

the three-digit regular production

option code the RPO code that you can

find on label in the back of the Bolt EV if

you take out the lower compartment

carpet and look in what looks like a

spare tire tub, there's a label on the

driver's side that has a whole bunch of

three digit codes on it

MMF just means that's which transaxle

or transmission this vehicle came with.

Okay right here on the top of the trans

axle is the transmission range selector

actuator and this is a brushless DC

motor with a gear reducer that actually

moves the shift lever to put us in to

Park reverse neutral Drive and low, now

technically inside of this drive unit it

there's really only park and not park,

but there is a position sensor in here

called an internal mode switch that will

monitor which position the transaxle

range selector is in so that the vehicle

can act appropriately. For example the

shifter itself on the center console is

not directly connected to the drive unit,

it's just an input to the computer that

controls this actuator, so when we go to

the reverse position for the neutral or

drive or low, there's a feedback on the

internal mode switch electrical

connector right here, that lets the

engine control module, even though this

doesn't have an engine, know which gear

range you have selected so that it can

request the trends axle act

appropriately. Also, right here by the

electrical connector for the internal

mode switch is the transmission fill

plug, so if you want to put fluid into

this transmission you need a 14

millimeter wrench or socket to take this

plug out and put the Dexron HP fluid

into the transmission. There are two

drain plugs on this transmission, one for

each side, so there's one down below on

each end of the transaxle the driver's

side and the passenger side, there's

there are two separate drain plugs to

get the fluid out of each side, now

there's only one fluid that goes

throughout this entire transaxle but

because of how its baffled and set up

inside to remove all the fluid you need

to remove both plugs.

Now speaking of fluid and fluid level

when you drain fluid at whatever the

recommended fluid change interval is or

if you're doing service work on the

transaxle here and you're adding fluid

you need to know when to stop adding

fluid, so on the other side of the

transaxle right here is the transaxle

fluid level check plug, so the drain

plugs right down here, the fluid level

check plugs here, the fill plug is on the

other side so you take the fill plug out

you take the fluid level check plug out,

and you add fluid until fluid comes out

over here, and then you let it sit and

stabilize for a minute add a little bit

more and make sure that fluid comes out

comes out to a slow drip, and then the

instructions tell us to put both plugs

back in and go drive the vehicle until

the transmission fluid temperature

reaches 35 degrees Celsius or 95 degrees

Fahrenheit and then double-check the

fluid level again to make sure that

comes out at a very slow drip. Alright,

while we are here on this side of the

transaxle we have an electric motor an

electric pump for the transmission fluid

so there's a big filter we'll see when

we take this thing apart down the bottom

center of this transaxle it will pull

fluid up from the filter and then put it

into what's called the oil sump so the

oil sump is basically just a great big

bathtub looking area up here that the

pump fills full of fluid and then there

are these little drain channels that

fluid drains down to cool the stator

windings and lubricate bearings and so

on and we'll see that once we get the

cover off so we have an electric 12 to 14

volt driven electric motor that pumps

fluid throughout this transaxle. From

what I read this pump only works when

you are in Reverse or Drive, it does not

pump when you're in park or neutral.

Alright, we have another electrical

connector right here, this connector is

for the resolver which measures the

angle of rotation the direction of

rotation and the speed of the electric

motor rotor itself, and then there's a

transmission fluid temperature sensor

that is in the bottom of this

transmission case cover here. All of

those are accessed electrically through

this electrical connector right here. As

you may have seen in my other video on

high-voltage components we have the air

conditioning compressor of the bolts up

here and then we have our coolant pipes

that go into what's called a coolant

sump in the bottom of this transaxle and

we'll see that here in a few minutes but

we have coolant going in coolant coming

back out and goes through a series of

cooling fins and cooling circuits to

absorb heat from the transmission fluid

right here on the back we have the

electrical connection for the

three-phase cables that come from the

the

single power inverter module that sits

two modules above here. Three-phase

orange cables come down to drive the

electric motor, there's a cover

the cables bolt on and then there's a

cover they'll holds the cable in place.

We have a transmission vent right here,

let's just take that vent off while we

vent tube off while we're here now you

can see the oil sump area again on the

top and the cooling sump coolant sump

area here in the bottom all right there

is one additional plug on the side of

the case with the electric motor and

there's nothing in the service

information to indicate this but I

believe this is a pressure test plug to

check the pump output pressure, but I

can't find any information on what that

fluid pressure should be. Okay, I'm going

to be disassembling this transaxle right

here on the workbench but there actually

is a special fixture to hold this

transaxle and allow you to rotate it and

disassemble different pieces of it and

still be able to rotate it for

convenience. I have this special adapter

as you can see here in this photograph

but the way it's mounted it's too high

and too difficult for me to disassemble

in that holding fixture being in a

wheelchair, so the workbench is where I'm

going to disassemble it, but I wanted you

to know there is a special fixture for

that and I tried it it just doesn't work

for me.

by the way this transaxle weighs about a

hundred and seventy pounds or 77.4

kilograms. Okay, well we're ready to

start disassembly, the first step is to

remove this oil pump the 12-volt power

oil pump, it has three bolts right here

and a few seals underneath it as you can

see here there are two seals that seal

the pump to the transmission case right

here there are two bolts that hold the

cover over the pump gears themselves

there are no instructions on

disassembling this so I assume we're not

supposed to disassemble it but that's

exactly what I like to do

take things apart I'm not supposed to as

long as I can get them back together and

make it work again here we go we've got

a Jew rotor style oil pump there's an

o-ring right here that needs to fit in

this groove to seal and then the cover

just bolts on okay the next thing on the

list is to remove the left-hand and

right-hand output shafts that go into

our differential side gears in the gear

reducer this is the left-hand side right

hand side over there it calls for a

slide hammer and a old pilot bearing

removal tool for a manual transmission

so this is the pilot bearing removal

tool right here and a slide hammer and

we are supposed to put this up inside

and put it into the snap ring groove for

the CV shaft and then pop it out well

come to find out the snap ring groove is

thinner than the tip of this tool that's

supposed to go into it and I didn't

realize that's what the problem was and

I had a hard time getting these output

shafts removed I finally got him out but

once I got a mound got looking at the

tool versus what they were supposed to

be grabbing I realized I need to grind

these down make him a little thinner so

that they'll actually fit into the

grooves of the her for these CV shaft

snap rings that are there so since I've

had this entire transaxle apart before

and I'll put it all back together

I've removed those snap rings they'll

hold these output shafts in place so I

can just pull them out by hand right now

this big long left hand output shaft

goes right through the center of the

rotor of the electric motor itself it's

it's hollow in the middle

and it has a big heavy-duty bushing

right here on the outside with the axle

seal and this is our left-hand output

shaft and then the CV shaft itself plugs

into here that goes to the left front

hub and bearing assembly and tire and

we'll assembly so there's our left-hand

axle shaft there's a snap ring that fits

in that groove right there typically and

I've just removed and I've just removed

that snap ring for ease for this

demonstration here obviously I'll need

to put that back in when I reassemble

so that's the left-hand axle shaft on

the other side we use the slide hammer

again and pull out the right hand axle

shaft as you can see this one is much

shorter than the other one and it has

the support bearing in the differential

case itself that holds it in place and

its own snap ring that I've already

removed and of course an axle sill here

on the other side as well okay the next

thing on the list is to remove this

transaxle case to remove the case I've

got to take the linkage off and our

actuator off and then we've got these

bolts to go all the way around and then

we'll be able to see the gear reduction

transfer gear and the final drive ring

gear and differential gear set so I'll

take the clip out and lift up for a

linkage on the shift actuator and then

take the bolts out

okay here's the shift actuator assembly

itself transmission range selector

actuator kind of a great big piece I

I've seen some of these that are smaller

right I'm not sure why this one is so

giant I'm not I've never seen one this

big but it obviously does the job of

mechanically shifting the transmission

range lever since you have an electronic

shifter on your center console alright

let's take these bolts out of the trans

transmission case okay I've got all the

bolts out of the transmission case now

we can attempt to slide it off it has a

couple of dowel pins they'll hold it in

place there's a couple of pry points

plus one right back here and another one

right here there we go

I'm going to come in with a plastic

mallet here and just tap lightly there

we go okay we can see inside of the

transmission case itself and the only

things in here of real interest are the

transmission internal mode switch right

here we got the electrical connector

right here harness right there that

connects to this outer blue connection

connector that will read which Range

Park reverse neutral low you have

selected with your transmission shift

lever and then we have the parking

linkage right here we've got Park

reverse neutral Drive

and low now of course normally

transmission fluid would would be

pouring out of here of whatever didn't

get drained out when you drained it

previously but I've had this apart and

cleaned everything up before we have our

ring gear right here and our

differential gear set and as notice we

have real nice ball bearings here these

bearings since their ball bearings

instead of tapered roller bearings have

to have in place shims so there's a

special shimming procedure to control

the end play of these bearings that will

have to go through when we reassemble it

so you're supposed to take these shims

off and throw them away well and then

replace them with new new ones when you

go back together I suggest that you take

them off and measure them and then hang

on to them because you might you might

need them again when I took these off

previously and measured them they were

almost all identical in the thickness so

there are six of these shims for the six

ball bearings that are in this transaxle

four of these shims measured exactly

half a millimeter in in with the other

two one of a measure one millimeter in

width and the other one measured 0.9

millimeters so you need to keep track of

what thickness shim you had where and

write those down so that you you'll have

an idea of at least what it was before

you took it apart now if you're just

going back together and you haven't

changed any shims or any parts inside

just reuse the old shims but if you're

changing a bearing or any of these

internal pieces you need to go through

the special measurement procedure that

we'll see when we go back together to

determine if these shims are correct

okay so there's there's special shims on

each of these

bearings I've measured all of them RIT

written their dimensions on the ziploc

bag here that I keep them in and will

refer to those when we go back together

all right now we just need to remove the

counter gear right here and the final

drive a ring gear and differential gear

set this is where our short little

output shaft plugged in right here and

then our long one came all the way

through on the other side okay before we

remove these gears there is a an

aluminum gasket with a rubber seal

embedded into it the instructions tell

us that is not reusable

there is also an oil baffle right down

here to channel transmission fluid away

from the ring gear to reduce losses as

it rotates into it and to splash oil up

into different channels to lubricate the

the bearings if we look in this case

half right here you can almost see what

looks like a funnel right there for the

fluid to drain back down and lubricate

this outer bearing and a similar one

here on this other other side for that

bearing so we've got a oil baffle to

remove all right I've got the oil baffle

removed on the other side of that is our

magnet for metallic particles from gear

normal gear wear and other malfunctions

okay now we're ready ready to remove

these gears pull out on the counter gear

and then pull out on the final drive and

it'll come right out if you don't pull

out on that counter gear first there's

not enough clearance for the final drive

Unit two clear so here's our final drive

you can see our open differential gear

set inside there here's our sim on the

other side as well

all right the instructions tell us that

we can if we won't want to remove the

park linkage in the internal notes which

I don't really care about that that's

just regular stuff that you'd see in any

other automatic transmission so let's

continue on with things that are unique

to the bolt

evie drive unit here the one ET 25

transaxle so let's turn the transmission

case around and we'll take off the

transmission case cover here on the

driver's side

now the SAE document the details the the

bolt evey drive unit here that I told

you about in the high voltage component

video tells us that the drive unit

itself was designed to be serviceable in

the vehicle that's why they have a case

removable case cover on one side and a

case cover on the other side for the

gear reduction unit you can leave this

Center portion with the electric motor

in it in the vehicle and just remove one

or both case covers to do service work

on components inside the case covers

seal replacements resolver replacements

internal modes with replacement and so

on but anyway we're going to take off

this case

cover next from the driver's side all

right this case cover is going to be a

little harder to get off than the other

one because the rotor that has internal

magnets embedded inside of it has now

magnetically pulled itself over to the

stator because we are no longer

centering it inside of the stator itself

and so it puts a it pulls it off to the

side just a little bit so there's a

prying

right here

and there's a pride point right down

here another prior point right here

there we go okay so here's our case

cover and it has an aluminum gasket

that's not reusable as well our case

cover has this long transmission filter

that's not serviceable without

disassembling things as you can see has

a temperature sensor down inside of it

right there and then this is our

resolver our serviceable resolver that

measures the position speed and

direction of rotation of the electric

motor rotor inside the transaxle here

let's turn this around oh by the way

down inside of the bearing housing there

is a shim for the ball bearing right

here on the rotor itself so we're

looking at the stator and the hairpin

six conductor deep stator design a

unique design we'll talk about that a

little bit more once we get the stator

out we have a lubrication channel right

here where fluid is going to drip out of

our oil sump and run along and drop down

on to the stator windings themselves and

cool the the stator windings it also has

a drip channel that comes over and goes

down to this bearing here to lubricate

it

so we've just got an 8 millimeter head

bolt holding the filter in place and as

you can see the filter just has an

o-ring seal on the one side and you can

see the pick up filter screen filter

element on the inside so this is going

to reach all the way in up underneath

the the stator itself to pick up the

fluid on the back side of it and on the

back side of it is the inlet of the

coolant so that would be the cooler oil

on the back side there all right then on

the resolver it just has eight three

eight millimeter head bolts to hold it

in place and one electrical connector

this resolver only bolts in in one

location it's not adjustable it has

automatic learn unlike the older Toyota

Prius resolvers that that would actually

come out of alignment

if you unbolted them and there was no

way for you to line them back up okay so

here is our resolver pull back on the

connector position assurance clip

depress the tab and remove the resolver

itself the resolver is a serviceable

unit when and if it ever goes bad but it

should should never go bad all right

then the remaining wire harness and the

pass-through connector here just goes

over to our temperature sensor okay next

on the list we need to remove what is

called the center support this is what's

supported the driver's side ball bearing

of our differential case assembly

okay this is our center support it's

held in place with six bolts and aligned

with two dowel pins right there now with

that removed there's nothing to stop our

transfer gear from sliding out it's just

a tight fit on the bearing in the bore

as it should be just pray lightly

sometimes these will just slide right

out and right in and other times they'll

they'll fight you here we go okay so

here's our transfer gear it's ball

bearing and shim so put that shit over

here with the others okay right here in

the end of the case we still have a

lubrication channel right here from the

oil trough the oil sump I mean right

there and then we have a cover for the

three-phase electrical connector right

here as well then on the other side we

have that oil distribution channel right

here that cools the stator so we've got

to remove that we are now to the point

where we are ready to pull this rotor

out but we just can't grab on to it and

pull it out it has some super strong

neodymium magnets multiple layers envy

configuration inside of this stator

you're not going to pull it out by hand

and you sure don't want to come in here

and start prying on it so the only way

to get that rotor out of there if you

want to remove it for service replace a

bit bearing on it or the gear on the

other side or another bearing or just

replace the rotor itself for whatever

reason loss of magnetism and trouble

code sets or whatever

it takes a special tool to pull it out

without having it rub on the stator

frame itself and without having it

injure you with you trying to pull it

out and it's pulling back in with all

its magnetic strength so true get that

out there's a special guide tool that

will hold it centered in the stator and

we need to set that up next and it

starts on the other side here so there's

a special tool kit that costs almost a

thousand dollars to Center this rotor as

you pull it out I found one on eBay for

a little bit less than that but but it's

a very expensive tool but if you want to

do service work on this transaxle you've

got to have it so let's bring in the

special tools okay so I brought in the

special tools to keep the rotor centered

there's a special spacer with a notch in

it to clear that notch right there this

is just gonna fit in there just like

that then there's a plate that bolts on

over the top of this to hold it in place

these don't need to be super tight

they're just holding that little spacer

in place so I'll just lightly Snug those

up then there's a sleeve here that's

supposed to fit down the center of that

rotor but these sleeves are a little bit

too big I've had to take sandpaper and

send them down to make them fit inside

of this rotor and I don't know if that's

because the tools were made for a first

design rotor and then they changed it or

if they just made the tools incorrectly

but these tools are from what used to be

can't more tools the special tools

supplier for General Motors it's now

Bosch service solutions so Bosch you may

want to take a look at this this tool

here the DT five two zero one one

- one - three because it doesn't fit

it's not doesn't Center up inside the

the rotor as well as it should

i've had to sand it down just a little

bit and then i'm able to tap it in a

little bit there but I think that it's

supposed to be if it's supposed to be a

tight fit but it should be able to slide

in by hand I believe then we have a

guide pin that's going to go through the

center of that then we have this outer

housing the bolts in place to hold the

guide pin in place so the blue sleeve

this one here because there's one for

the other side also centers the rotor

into this plate and then this sleeve is

centered into this plate so we've now

centered the rotor on this side of the

stator so now we need to go to the other

side to put additional tools in to get

it centered and then pull it up and out

okay at this point if I had the

transaxle mounted in that special

rotating holding fixture I would just

simply rotate it on its side and get the

get the rest of the tools hooked up but

I don't I'm not able to use that so I'm

just going to put some extra long bolts

in this side of the case to hold the

case up off of this tool when I tip it

over to support it as we pull the rotor

out

okay so here we go we're going to tip

the tip the whole thing up on its hand

just like that so now we've got

clearance for the tool underneath and we

can get the upper tools set up to pull

the rotor up and out all right while

we've got the transaxle tipped on its

side let's take this oil sump cover off

and show you what's inside of there so

it's just a big empty trough and you can

see has one two three four five six

holes in it where fluid is going to go

out and drip down on other parts inside

of the transaxle for stator cooling and

for the ball bearing lubrication the

cover itself has that same aluminum

gasket that's not reusable also while we

have this transaxle on its end let's

turn it over and take the coolant sump

off next okay here's our coolant sump

you can see this pipe right here is

where the coolant comes in and it has to

wind back and forth back and forth and

then come back out over here the coolant

sump which is visible from the bottom of

the car with the under car cover removed

also has that same aluminum gasket

that's not not reusable why are they not

reusable I don't know maybe the aluminum

crushes these I'm going to see if I can

buy replacement gaskets at the local

Chevrolet dealer it seems like I saw a

service bulletin saying that all these

parts are serviceable now and it gave

the part numbers for them but if not

none of these are damaged it only has 35

miles on it and I'll reuse them and see

what happens

okay so coolant sump oil sump so now we

are ready to pull out the rotor assembly

so to pull out the rotor assembly we

have a guide pin it's going to come in

and screw into that dowel they had a

threaded end on it all right so this

threaded guide pin did not line up

exactly perfect with the guide pin down

below I can't tell if we're just

spinning the whole thing there we go

all right it's screwed all the way into

that alignment dowel from below now we

have this tool that has three holes that

go over the holes where the stator bolts

are so we need to remove the stator

bolts next these stator bolts are not

reusable three stator bolts so we put

this tool over the top of that we want

to be very careful that we don't damage

pry lean or set anything on the stator

windings here that could cause damage to

them so we'll get that lined up just

like that now I'm going to reposition

the camera so you can see

how tall this next tool is that fits on

here all right we have two clamshell

type tools that are going to come in and

clamp down over the resolver cam rotor

there and this bearing they're gonna go

just like that except I need to split

them apart so I can get the next tool in

it says this big tall piece right here

that's going to go over and down into

our stator bolt holes so we've got this

threaded shaft we've got this adapter

right here that these little clamshell

tools are going to hook into and then

the threaded shaft with a nut on the top

of it we're going to tighten that nut

and pull the rotor up out okay so the

tricky part of giving this hooked up is

getting both of these

clamshell tools over this lip right here

so I have to loosen the nut on the top

and let it come down let me turn this

you can see what's going on

there we go okay so we slide that open

clamp the clamshells around it put this

sleeve over the top of it to lock the

clamshell in place snug up this nut to

hold the lock in place and then from the

top here we start to pull up on the

rotor itself I'm going to get

repositioned bring my chair up a little

higher here so I can reach that nut it

takes quite a bit of turning to pull

that out okay here we go thirty

millimeter wrench we want to turn the

nut and prevent the shaft from turning

so I'm just going to hang on down here

as it comes up those guide pins the

guide dowels keep it from rubbing on the

stator frame although although there's

almost a strange ratcheting sound as I'm

pulling this out that makes me think

it's barely contacting the the stator

laminations or the rotor laminations

anyway we'll pull it out and take a look

see if we can see any witness marks you

can see the top of the rotor now is

starting to appear

I think we're finally clearing the top

of the yes we are it all of a sudden got

real easy to turn the nut so we no

longer have the magnet pulling out or

resisting us pulling out okay you can

see the entire length of the rotor here

get another bearing down below it and a

gear below that now we're supposed to

just lift up on this and and pull it out

I'm not sure if I'm strong enough I may

have to bring in the the engine hoist to

pull it out of here but it's just

sitting on these three non-magnetic

aluminum poles here and we've got the

weight of the the rotor assembly itself

I measured it earlier but I can't

remember what it is at this moment but

let's see if we can lift this up and out

though I cannot so let me get the engine

hoist we have to lift it up high enough

to clear that alignment dowel so I've

got to lift it up probably four more

inches 100 millimeters or so okay I've

never tried this before it's just a lift

strap let's bring it up

okay the lifting or the tool was getting

stuck in one of the holes for the the

stator bolts there we go

okay here we go

and we've cleared the alignment dowel so

slide the case out of the way here and

we'll let that back down

oh let's see how much that weighs it

says it weighs 60 pounds with the tool

the tools probably 10 pounds of that

okay we have to remember that this rotor

is highly magnetic very strong eight

pole magnetic field around this thing

and so we need to keep it away from

anything any metal particles or any

tools or anything else that could cost

cause it to receive damage on its

laminations here in looking at the the

laminations from removing it I don't see

any obvious damage at all there let's

let this down and take the the tool off

and just look at the rotor itself

little clamshell pieces out of there

these tools are magnet earth iron some

some sorts so we got to keep those away

from the magnetic field as you can see

these blue bars are aluminum they're not

sticking to the the rotor itself and

then plastic of course works great with

the magnetic fields so now we've just

got our rotor we've got our drive gear

down here I've got a ball bearing and

another ball bearing there's another

shim down inside the case a bigger

diameter shim for this bigger diameter

bearing all right I'm going to get some

wooden blocks to put this in all right

here's the rotor for the bolt

evie as you can see this bearing seems

to have some sort of a gray coating on

the outer race where this one does not

and on the counter gear bearings they

also have this gray coating it doesn't

say anything about what that gray

coating is for I suspect it's to prevent

corrosion from the dissimilar metals

with possible induced currents going

through them with the the motor running

vehicle going down the road I've seen

this type of coating on universal joints

in universal joint caps universal joint

caps bearing caps in an aluminum

driveshaft the same color I don't know

if it's the same material but if any of

you know what this coating is for if

you'd please put that in the comments

below I'd appreciate that

I'm just speculating okay so we've got

the rotor out of the way this is a

serviceable piece now the last piece to

remove is the stator assembly itself and

it has three special guide pins that go

into the stator bolt holes and screw

into the transaxle case and then they're

tapered on the top here and that's to

allow you to slide the stator out

without it binding inside so I'll slide

that over there rotate it down and just

pull out slightly

here it comes just like that so here's

the stator for the Chevrolet bolt Eevee

if we zoom in close and look at the

stator windings you can actually see

there are 1 2 3 rows of these hairpin

conductors which means they are 6

conductors deep in this stator and from

what I read in the SAE document on this

new improved motor that helps reduce the

AC power losses at the higher motor rpm

a typical stator like in the previous

Chevrolet Volt had 2 rows instead of 3

so they were four conductors deep in the

Chevrolet Volts and six conductors deep

here and one of the people that was on

the original design team for the

Chevrolet Volt told me that when they

designed this electric motor and it's

designed for maximum efficiency and hand

power that there was no other motor out

there that could even match the

efficiency of this motor and they said

that they designed this motor to be the

next small-block Chevrolet so to say of

power trains so the small-block

Chevrolet was and still is a very

popular very powerful v8 engine and has

been for many many years and their

intent was to have this motor design

maybe even this drive unit be in

multiple platforms with the same high

power high efficiency motor system if we

look at the other side here of the

stator windings you can see the the

other end of the hairpin conductors and

then there's a drip channel right here

for oil to come out of that oil sump and

to drip down and go down and lubricate

the stator windings because these get

really hot this is the heat source

inside of the transmission and it and

although it gets hot it doesn't get as

hot as the fluid

although the fluid gets hot it doesn't

get hot as a normal planetary gearset

style automatic transmission and the

cooling system surge tank reservoir cap

was only pressurized to 5 psi for this

loop of the cooling system so much lower

amounts of heat compared to an internal

combustion engine with a torque

converter heat generating planetary

gearset style of automatic transmission

now just a couple of things to get

wrapped up with this disassembly video

because we will reassemble it showing

the special measurements for the shims

and everything when we go back together

but one thing I wanted to show you about

these electric vehicles is how simple

they are and when I mean when I say

simple I don't mean simple design

meaning it was easy to design these

simplicity is not necessarily easy but

if we look at the number of rotating

parts in this entire drive unit

there are basically three main rotating

parts we've got the rotor assembly that

then turns the counter gear right here

that then turns the final drive three

pieces no clutch packs no bands and no

sprags no roller clutches no Pistons

none of those hundreds of parts that you

would see in a typical automatic

transmission let alone the internal

combustion engine that this is replacing

of course there are three main moving

parts these pieces here but each one has

two bearings on it so there's six more

pieces so there's nine total and then

inside of the differential here we have

two side gears and two differential

pinion gears so that makes for a total

of 13 possible moving parts inside the

of this drive unit and only when you're

turning corners would the side gears in

the differentials

be rotating at a different speed than

the differential case so a real basic

very reliable system these electric

vehicles and and this one is is very

efficient and that the design is very

compact to where this left-hand output

shaft remember goes right through the

center of the rotor instead of being

offset like on the the Nissan Leaf and

other electric vehicles out there so

congratulations to Chevrolet and the

design team that came up with this

amazing and efficient and simplistic

evie drive unit and I think it's

absolutely beautiful so coming up I hope

to shoot a reassembly video with all the

measurements for this drive unit and

then we've got all of these parts out

the drive unit all of the electronics

and our and our Chevy bolt back here on

the hoist is totally empty yeah under

the under the hood so we've got to put

that all back together and and make it

work again even the battery is out the

whole thing is stripped as far as the

powertrain is concerned and we're gonna

put that back together and and make it

work and hopefully get it converted to a

DC fast charge thank you for watching

2017 Chevrolet Bolt EV: Regular Car Reviews

RegularCars:

Nice Sonic!

♫Bolt, bolt, bolt, bo-bo-bo-bolt, bolt bo-bo-bo-bo-bolt♫

2017 Chevrolet Bolt EV

Crap seats.

Garbage dash.

Masturbatory gear selector.

Hard seats.

I POOP

Cheap plastic-

UHH UNSTOPPABLE

Crashy suspension

I POOP

MY ASS

IT CONTINUES

HNNNNNNNNNNGH

ONE TWO THREE FOUR FIVE SIX SEVEN EIGHT NINE

TEN TEN TEN TEN TEN

I POOP I POOP I POOP

AND THEN I brown.

So this Bolt makes the equivalent of

200 horsepower and 266 pound-feet of torque

on a 150 kilowatt electric motor.

Now that's about the equivalent of a

Fiesta ST with a tune on it, and a

Chevrolet Bolt is about the size of a Ford Fiesta

It's got a 60 kilowatt-hour battery,

which is the same as a high-end Tesla,

which gives it an effective or claimed range of 238 miles

BULLSHIT

I'll be surprised if you crack 200 if you drive this thing normally.

The Bolt also offers

regeneteraviivivee

braking, which means city driving is more efficient for battery life than highway driving since you're braking more often.

On your standard 110-120 volt house current,

the battery takes two days to recharge,

although if you have 240 power and the appropriate adapter, it will charge in nine hours.

So Andy, paid the extra

$750 for the DC fast charging capability, which probably sounds expensive,

but considering Andy got this car as part of a buyback deal with his old Volkswagen Golf TDI...

turns out to be a pretty good deal.

Hey. It was either this or a Nissan Leaf,

and based on our experience I can't really blame Andy for making the choice he did.

Okay, the Chevy Bolt is a

$40,000 car. Ugh...

And this interior...

Shittiest interior I've ever been in!

I'm talking Chevrolet Cavalier

BAD

The seats feel like cafeteria chairs with all the bolstering of a church pew,

and the dash plastic is harder and grayer than an IBM keyboard.

And the gear shifter! All right look-

This is an automatic shifter that makes sense. Look.

Park.

Drive.

Overdrive.

Drive.

Low.

You could have any type of mnnnhhgh

Hngh.

Look. And this thing, they were able to make normal stuff.

This has a physical connection to the transmission.

If you have an electric car you don't have to have a physical tra-

Look at all the stuff coming out this.

you don't have to have a physical connection to the transmission,

so you could have it be anything you want.

So if it could be anything you want, why not have it be simple that people can understand?

But instead you had to make something more complicated than a

complicated original shifter.

Do you hear me?!

But no.. you had to make it complicated

Hold down the missile button and move it up and to the left to reverse.

But not right and down to drive, just back! But Park is a different button

and it doesn't work like the side missile button... You made it complicated GM

because complicated means fancy.

The handling pushes nothing but understeer, which is fine.

It's an economy car. And the acceleration is good. It's good. Not Tesla good. I mean zero to 60 in 6.5

seconds on a full charge and zero to 60 in 6.7 seconds on a 60 percent charge.

That's good!

And it could probably reach top speeds well over 100 miles an hour

if the engine wasn't electronically governed

so they can't go faster than 93.

Governor kicks in at 93 miles an hour. I mean I can sorta

see why you might not want to indulge the sort of guy who would really want to push an economy car up to

speeds past 100 miles an hour.

It probably has something to do with the electric motors.

I'll bet they could spin faster.

But giving that there's no gearing. You know it's one to one,

the car will only run as fast as these engines will turn

Er, I'm sorry, the motors will turn.

But 93 miles an hour seems like such an arbitrary number.

Why not 90 or,

or 95

But what's crazy is that even in its upper register,

the motor is still quieter than the kid blowing on a pinwheel.

Sort of like a Michael Bolton b-side,

but under 15 miles an hour, this little speaker turns on in the front bumper that goes like this

*heeeeeeeeeee*

It's -- it's it's a white noise machine in the front bumper.

It makes a noise similar to air conditioning fans. The idea is this is supposed to alert people

to not crash into you.

But when Roman was driving it,

he almost hit a squirrel so that didn't hear.

Although I did hear this car coming on one of the drive-by -- you know -- shots that we do.

So, it works

But car guys want the ability to turn stuff off. They're like PC users.

"No, I don't like that weird noise, just turn it off."

"I'll deal with the repercussions."

And it doesn't help that the tone that that white noise generator makes isn't particularly distinctive either.

It sounds a bit like an old dial-up modem from the "jerking off to music videos on RealPlayer" era.

"Get off the phone mom, I'm trying to get on Prodigy!"

But when the white noise machine is turned off, this car is quieter than a church after somebody objects to a wedding.

At 3,580 pounds this car is heavy, but quiet, like a BBW with low self-esteem.

It's heavy, but quiet, like a powerlifter on a blind date.

It's heavy, but quiet, like The Passion of Joan of Arc

It's heavy, but quiet, like the constant dependable love of your

LEFT HAND.

It still has a standard 12 volt lead acid battery to run accessories and get the car going before it "gets going",

but ugh, the interior!

Ugh!

At first glance it looks nice, but on closer inspection,

you can see it's all cheap, plastic components,

like they spent so much money on the engine, that they didn't have the budget for anything more than

Walmart seat backings.

I mean you pull up the carpet, and there's a lot of seam sealer too. I mean that's good,

but it's just kind of *phbbt* on everywhere.

Adding to the cheap feel of this car. And yes,

it's a low blow coming from a guy who drove a car called "Silicone Sally",

but my point stands.

Okay one thing that does really, really well, is a little paddle. On the left hand side of the steering wheel.

What that does is it kicks on your regenerative braking,

anytime you want it.

It has nothing to do with your brake pedal.

You can if you want,

come to a stop every single time without ever touching the brake.

If you time it right, and pull that little lever in.

And it doesn't matter what mode the car is in: regular drive, sport, sport low -- anyway

It will bring the car to a dead stop without using the brakes, and that's fun.

I could dig that. And I know I don't think I'd ever get a 200 mile range out of this car

Because it is fun to accelerate.

Again, not Tesla fast, but fast. Fun.

And you can make the front tires squeal.

*The second we can get around this -- hello, Toyota*

*That's how I used the regular brakes there*

*tire squeal*

*Whoa?*

*Sorry, I hit th-- i hit the accelerator mid corner, and it just -- and it just broke the tires loose*

And it does surprise you. Even as electric cars gain in widespread acceptance,

some people are just never going to warm to electrics.

I think one of the reasons is that for some people

accepting electric cars is passively approving the plan to phase out internal combustion engines.

More than a Tesla or a BMW i3 or any other electric car on the market,

the Bolt reads like a thesis statement on the decline of the internal combustion engine.

Because when your regular cars start getting electrified,

when you start getting electrics that are this accessible, this affordable, this thoughtlessly fun,

that's when you really start to wonder --

do all those clickbait thinkpieces about the death of the internal combustion engine have a point?

It's been predicted by financial analysts that the total cost of ownership for an electric car,

will be on par with the cost of a

gasoline-powered car, before 2020,

while electric vehicles could account for as much as 14 percent of worldwide car sales by 2025.

That's kind of insane when you consider that

globally, electric cars really only account for about 1% of all sales in 2017.

But it makes sense that affordability would be a motivating reason for people to hop on the electric car bandwagon.

Not only are the cars themselves getting cheaper --

AND THEIR INTERIORS --

But their components --

INTERIORS --

as well.

With batteries gradually falling in cost in addition to the price per kilowatt hour

plummeting from over $1,000 in 2010,

to just under $200 today.

That's without even getting to countries

who've pledged to go electric. Of course, a pledge doesn't mean anything.

It's like an initiative, which George Carlin said "an initiative is an idea that isn't going anywhere"

so I don't put any stock in Britain saying they're gonna guarantee all new cars to be zero emission by 2050.

I don't think that's happening. In fact

I don't... I think we'll be still making internal combustion engines 100 years from now.

Because it's not really the viability of the car that's in question,

it's the viability of the infrastructure.

And that's one serious problem with the Chevy Bolt.

It can't use Tesla's fast charging stations. It has to use...

There is no, there is no

infrastructure to support this car. You get a Chevy Bolt, you're taking a compass to your map, and

drawing a hundred mile radius around your house. That's all the farther you're gonna go

if you don't want to have to deal with range anxiety.

A Tesla can go coast-to-coast.

There is enough Tesla fast charging stations for those cars to work.

But we're in an early era now with electric cars in the same way we were with computers in 1991.

Nowadays everything that plugs into a computer is a USB, Universal Serial Bus.

But back in the early 90s you had all sorts of different ports

and you got a digital camera? There was no guarantee there would be the right port on the computer. Is it a PS/2? Is it a serial?

Does it plug into that game port that's on your sound card? Your Sound Blaster card?

We don't know. All different electric cars right now have different kind of a charge -- have different kind of charging ports.

We need a universal charging port for cars,

and that's one thing that Tesla's doing.

The long term goal of Tesla is to be more of a power supplier than it is an

automotive company. Plus in rural places like Pennsylvania --

There were no charging points down near Philadelphia and in Kutztown, Pennsylvania where we filmed this.

But back to the Bolt itself.

If you convince yourself you're driving a Chevy Sonic, then it's fine.

If you ignore the cost you spent, and if you get all the deals you can, if you can find a way to knock down

with the government incentives and maybe a work incentive and other tax breaks --

if you can get the cost of this from

$40,000 to under 30 in your mind, you won't be upset with the interior.

But if you pay sticker for this,

you're gonna hate this interior.

Just a pair of, Recaros or Sparcos would make this interior so much better.

I mean, screw the guys in the back, keep the crappy seats in the back. You kind of expect that.

But if you spent $2,000 on better seats, I think people will be willing to pay

$42,000 ,over $40,000, if the front seats were better.

Ughey. There's another problem with electric vehicles as well.

Garages. What are you gonna do, have this thing on the street?

What are you gonna do? Drag an extension cord out your window, have it go across the sidewalk and into your car?

Yeah, I guess?

But what about knuckleheads in your neighborhood?

Yeah, plugging your car overnight and have this thing dangling out your window. Then along come two lowbrow

knuckle-draggers with a very low class rank, and they see your electric car and your extension cable. And of course they're out late at night

because their parents are pieces of shit too - and they just yank the charging cable out of your car.

*knuckledragger voice*

Ha ha, faggot!

Now you go out to your car, and there's no charge in the morning. So that's the big cost of electric cars.

It's limited to homeowners. Homeowners with garages.

So yeah, I get the pushback against electric cars not only from a jobs perspective, but an enjoyability standpoint as well.

It's just not the same, but not the same doesn't automatically mean bad.

There is a place for electric cars. Perhaps in the future there will only be a place for electric cars.

But the growing popularity of electric vehicles means

manufacturers will have to get more creative with the design, with the engineering, with the functions these vehicles perform,

and the methods by which these cars perform them.

But for as exciting as that has the potential to be,

automotive enthusiasts are going to want more from these electrics.

Especially if they're old enough to remember how things used to be. I don't know what the future holds,

but hopefully the compromise is in there somewhere.

♫Chevy Bolt EV's an electric car.♫

♫Don't fret on the range, it'll get you far♫

♫And the cost is low,♫

♫comparing to a Tesla, but it costs more than a Nissan Leaf♫

Installing RPI's C7 Corvette Grille Blackout Vinyl Overlay Kit

RPI Designs:

alright guys Phil here RPI design today

everyone tell you about our c7 vinyl

grill blackouts we're you guys know that

on the Stingray you've got the big

chrome strip across the front of the car

light guys can like it we came up with a

little wild drill overlay two quick easy

install there's a little soap and water an

old razor blade the only tools you need

will show you how it's done here right

now

all right guys when you get the kit

you'll see has three stripes only need 2 for your

car installed third one here it's just

in case you have a problem of one of

them so we'll go and I'll show you how

to do this right now

the little soap and water I said it'll

make this job a lot easier book here you

have a spray ball you can use that it's

not sponge paper towel whatever silver

water will help things help the vinyl

just slide across here so it's a lot

easier to work with

all right

pull off the first strip

so right here on the end

I didn't up here with the bottom of the

grill

the strip will be longer than what you

need you don't the place it perfectly

get it closed all you need to do the

grades are bleeding trim during the rest

okay guys you got this laid out here on

the car right now

so I says little soap and water few

minutes here make sure you don't have

any chrome shown anywhere once you happy

with the placement of it take paper

towel let's go over it here or go

towards the end work out any water to

have laying in back there behind it and

that will seal it right down to your to

your car

all right guys after you got all laid

out got the wire squeegeed out of it

take razor blade exacto knife right here

to the factory split into chrome trim

blade mer quick easy cut just like that

peel it off

it's a little bit louder and err that's

normal deck one back here is a little

bit trickier that's good a couple angles

here again it's not big deal nice sharp

blade

I need to I need to work that back down

in there a little bit there's risk we

might look it up a little bit and

also didn't cut always here is first

time there just cut back a little bit

here so I could see why I'm doing all

the better I got a little bit idea where

I'm placing my cuts

I feel the edge program

work it down in there a little big in

the look almost goodnight there for you

there you have

in play a little bit of water in there

and the edge there needed work coughing

in there I'll wipe that down paper towel

and you're down with that side leave

while reloading long side here you can

see the difference already than where

your car looks

alright guys we've got the first side

done on the second side again steps are

the same full silver water helps move it

around be careful here when you lay out

the second side here you don't want to

have problem here it might want to pick

up this and you start peeling off there

again just be a little bit careful put a

little soap and water on the outside

over here student causing any problems

okay guys we've got the second half laid

out here see your silky little bubbles

here's the little wrinkles that's normal

for vinyl again just take your paper

towel just work them out towards the

edges nine times out of ten the workout

quick and easy no problems if you've got

any problems you've got any bubbles you

don't want to come out and it's like a

day or two later and you're still there

you can take a spin pop them there lay

it off flat it look good as new

you can find this and many more parts on

our c7 Corvette on our website RPI

designs to see you next time

Driveshaft Vibrations - The NVH App

WeberAuto:

Hello, my name is John Kelly and this is

the WeberAuto YouTube channel. Today I am

going to demonstrate how to use the new

NVH app to diagnose a driveshaft speed

related vibration. I have a vehicle set

up with a vibration

installed on it, and we are ready to go

drive, do a road test, so let us set the

app up for the vehicle that we are

going to use here, so if we start the app,

agree, the vehicle that I'm driving is an

older vehicle that is not in our

database of vehicles, but you can

actually use this app on any vehicle

as long as you enter the vehicle

information that's required, so in this

case we will go with "Unlisted Vehicle" in

the upper right hand corner,

this is a four-wheel drive truck, so I will

click on four-wheel drive, we have to

enter the number of cylinders in the

engine, this is a six-cylinder engine, we

have to enter the rear axle gear ratio,

to find the rear axle gear ratio and we

have a link, that reads "Find my Axle

Gear Ratio" right there on the screen,

scroll down, this is a GMC, so we will select GMC. General Motors vehicles have a code

label somewhere in usually the glove

box or the trunk area, and you will find

a code that begins with the letter F or

the letter G, four trucks it is the

letter G, and this truck has a GU6

axle code, so scroll down to where you

find GU6

and look in the next column, it gives us

the axle gear ratio of 3.42, so we

will hit done, we will come to the axle gear

ratio box and punch in 3.42

it asks us for the transfer

case gear ratio on this

four-wheel-drive truck, if you're driving

around in two wheel drive, or four-wheel

drive high, what you normally wouldn't do

on dry roads, the transfer case gear

ratio is just simply 1.0, alright so the

next thing that we need is the

transmission gear ratios, so we will click on

transmission gear ratios, this is a

four-speed transmission, but notice we

can hit the plus or minus buttons to

select the number of speeds in the

transmission, and that this is a four

speeds, so I selected 4, we can just go

with default gear ratios if you don't

know your gear ratios are. but I do know

what transmission this this has. and the

way I find that out is to look at

"Find my Transmission Gear Ratios", the

link right there on the screen, and

scroll down to GMC, and on the code label

that I have on this truck, I have a M30

and so M30 here is a 4L60-E transmission,

and if I scroll over there is the

gear ratios; 3.059, 1.625, 1.0, 0.696, so I will come back here and punch in

3.059, 1.625, 1.0, and 0.696.

the app needs to know the transmission

gear ratios to calculate the rotational

speeds of some of the parts on your

truck, so the last thing you have to

enter for whatever vehicle you want to

test is the tire size, this truck has 235

75, 15, tires on it, so now we hit start, it

brings us to the "Vehicle View" where we

have a powertrain view of a

four-wheel-drive vehicle, and now we are

going to hit "Start Recording" and go

drive it and see if we can pick up this

vibration, so let us go ahead and and see

if we can find. I am going to sit the

iPhone on the dash, cover it up with the

piece of paper, so the Sun does not

overheat it,

let us go see what we can find.

there it is showning up

driveshaft

first order

it looks liee we have got a third-order tire along

with it

so here we are at 73, 74, miles an hour

we have got glowing driveshaft, glowing

tires, it looks like we have multiple

vibrations on this vehicle

looks like it is worse at the higher

vehicle speeds

driveshaft speed is around 50,

50 revolutions per second

I am going tell the app to stop recording,

we can get off and go back

I will give it a name 2001

GMC, Sonoma, with a D1 driveshaft

vibration and hit save, the app will analyze

the data it has recorded and tell us

thinks it has found as the source of the

vibration. Remember the app will give us

the highest average amplitude frequency

over the time that we drove, so it is

telling us to have a third-order tire

speed related vibration as the primary

cause of the shaking as we drive, and of

course you can click on "How do we fix

this vibration" brings up a help file

that tells you how to repair that, but lets

go back and look at the totals, notice we

have third order tire was detected

225 times during our

road test, and a first-order drive shaft

was detected 156

times, and let's see what speeds they

were worse at. On the third-order tire, it

looks like 70-74 miles an hour it was

detected 158

times all the other vehicle speeds were

pretty minor, let us look at the

first-order driveshaft, it was detected

109 times between 70 and 74 miles an

hour, and the rest of the time

looks like 50 to 54 miles an hour it was

detected 14 times, so a lower speed at

lower speeds it came in and again at

higher speeds.

Engine vibrations, there were few they

were picked up, second order engine was

the most, second order engine vibration

on a V-6 engine is is one of those

normal vibrations that we should not be

feeling in the passenger compartment, so

this old ruck actually has three

different vibrations, but the one with

the highest average amplitude of 0.148

was the third order tire, followed by first-order drive shaft at 0.169

now that is a higher amplitude, but it was only detected

156 times versus the

225 times for

the third-order tire, so it's not just

amplitude, it's a weighted amplitude

level based on how many times it was

detected.

let us look at our graph

there is a lot of blue there, that blue is

the drive shaft speed related vibration

this graph shows amplitude versus time

and the color represents the frequency

of the part on that on the vehicle

Okay, well, that is how to manually enter

into vehicle's information, once again

this app will work on any vehicle as long

as you can come up with the gear ratios

and tire size, and number of in

engine cylinders, and so on

it will work. Alright now the app

gave us help for the third-order tire

speed vibration, but if we go all the way

back to the first menu here, and look

under the diagnostic help icon, and then

diagnostic procedures, it has a separate

menu item, as you can see here, for tire

speed related vibrations, and it breaks

it down by the orders, drive shaft speed

related vibrations and the their

particular orders, engine speed

vibrations and their orders, and each

type of vibration has its own specific

diagnostic procedures that all of those

procedures are in these help file links.

while we are driving here, if we click on

if you go back to the main menu and

click on Tools, there is several tools

here are available and we'll take a look

at these in in different videos, but one

of them is just simply a vehicle speed

signal that would be based off of the

GPS speed signal as we drive, so it says

we are doing 33 miles an hour, and that matches

our speedometer

The GPS vehicle speed is actually more

accurate than your speedometer because your

speedometer is based on the tire size

that you have on your vehicle, and as

your tires wear out your speedometer

becomes less and less accurate, we have a

Live Data tool wherer we can just look at

the frequencies and the amplitudes that

are being measured as we drive down the

road, so it will show you the top five

frequencies as far as amplitude levels

with a tool, we have a strobe light tool

that will actually flash your camera's

flash a certain number of times per

second and will use that tool in another

video for engine, for abnormal engine

vibrations, and then we have another tool

for measuring driveshaft u-joint working

angles, and help for correcting those.

This has been a demonstration of using

the NVH app to detect driveline or drive

shaft speed related vibrations, It turns

out we picked up a few other unexpected

vibrations on this old truck at the same

time, thanks for watching.

Why it's Dumb to use Cartridge Oil Filters in Your Car

Scotty Kilmer:

one, two, three, four!

Rev up your engines!

It's time for the Scotty Kilmer Channel

today I'm going to talk about why I hate

these modern canister oil filters, where you got

to take them all apart and replace just the

paper part inside, now my first beef is

cost, now why does this filter cost more

than this filter, it's just paper, this

has all kinds of stuff inside it, they're

just ripping you off on the price, now

this is on a Toyota Highlander, and

granted I call up the Toyota dealer, at

least they're fair, they charge five

dollars for the paper one and seven

dollars for the metal one, at least

they're not ripping you off, but about

this one on a local auto parts store and

they charged tons more, usually the dealers

have the highest prices, so they're just

ripping you off with these stupid things,

I guess they figure, your not going to drive

the whole way to a dealership to save a

few bucks, but really, it's a ripoff that

they charge so much for these stupid

paper ones at auto parts stores, and

secondly, look at the difference,

these are spaced further apart, these are

closer together, so you actually get

worse filtration with these stupid paper

ones, and then of course, comes a problem of

getting these stupid things off,

because as you can see here, they're an

oddball shape, and you have to buy a

special wrench just to get the stupid

things off, and take my advice, when

you buy one, buy a metal one like this, I

tried the plastic ones, but they just

snapped off because they were so cheap

too, then when you put the tool on, you

have to take it off, which comes off with

a tool, don't ever try to do it with a

wrench or something because it'll just strip

it all apart, and of course it makes a gigantic mess, because you

got to take all this stuff apart, and oil

gets all over the place, now when I was a kid

in the sixties starting to work on cars,

they had old cars like this, I thought we

were going forward with technology, not

backwards, and then you have to put a new

rubber seal on it, lubricate that, and

screw it back on, now with modern

engines being so complex with variable

valve timing and other editions to them,

why on earth are they going to a cheaper

filter that doesn't filter as well instead of

using a tried and trued metal

canister one that we've used for decades,

I mean really, they have less filtration

area, they're a bigger pain to change, why

on earth are they putting these things

in modern cars,

well the only thing I can think that

they're thinking is, it's cheaper to

make them, because everything's plastic,

and since they don't filter as well, the

engines will wear out faster, then they'll

sell you another one, so there's planned

obsolescence involved too, but if you have one of these stupid oil

canisters on your car, take my advice,

when you buy a filter, buy one that's got

synthetic materials, so at least it's

going to filter as well as it can, and

last longer because the synthetic

materials don't break down as fast as

the paper does, I'm just happy that all

my cars are older and they use

high-quality extended life oil filters

on them, that are in a can, and remember

if you've got any car questions just

visit the Scotty Kilmer channel and

I'll answer them as soon as I get back

from the twilight zone.

2020 Subaru Legacy First Impressions; Should You Buy a Vehicle with No Maintenance History? | #218

Consumer Reports:

We give our take on the

redesigned 2020 Subaru Legacy.

Then we address

some controversies

around emissions

and fuel economy.

And finally, we

answer your questions,

including one about whether

you should stick with a stick

shift for a long commute.

Next on Talking Cars.

[MUSIC PLAYING]

Hey, welcome back.

I'm Keith Barry.

I'm Jennifer Stockburger.

And I'm Ryan Pszczolkowski.

And today, we're going to start

off by talking about emissions

and safety have

been in the news,

and it's been because

a series of tweets,

and those tweets are

from @realDonaldTrump.

Name sounds familiar.

So the first one

is, "My proposal

to the politically

correct automobile

companies would lower

the average price

of a car to consumers

by more than $3,000,

while at the same time making

the car substantially safer.

Engines would run smoother.

Very little impact

on the environment!

Foolish executives!"

And then the second one is, "The

legendary Henry Ford and Alfred

Sloan, the founders of Ford

Motor Company and General

Motors, are 'rolling

over' at the weakness

of current car

company executives

willing to spend more

money on a car that

is not as safe or good, and

cost $3,000 more to consumers.

Crazy!"

Why is he talking cars?

That's our job.

That's our job really.

So, Jen, why have these

issues sort of surfaced?

Amidst all the

chaos in the world,

why are emissions worthy

of presidential attention?

Right.

So a bit of a timeline,

just forgive me,

but what he's referring to is

a recent agreement with Ford,

also BMW, Honda, and Volkswagen,

with the state of California

that says they will agree

to improve fuel economy

emissions to a level in between

what previously California

was requiring and was

part of a federal mandate.

So California is kind of able

to do its own thing, right?

So let me step back.

So 1970s fuel

economy standards--

That far back?

Right.

OK.

2009, the Supreme

Court says, hey, CO2,

which comes from burning

fuel, is a greenhouse

gas emissions and now can be

regulated as an air pollutant.

So they had two phases.

Phase one was 2012 to '16,

phase two 2017 to '25,

and they had to up by about

5% each year improvement.

In greenhouse--

In greenhouse gas

emissions, which ultimately

relates to fuel economy as well.

So included in that

was sort of a waiver

to the state of

California, because they

had worse pollution

issues, that they

could set even higher standards

than the federal mandates

over time, and other states

subsequently followed,

including Connecticut,

where we're based.

So those were considered

the clean car states.

So that phase two mandate also

included a mid-term review

that said, in 2018, we're

going to review and make

sure we're on the right track.

Originally, they said, those

standards seemed appropriate.

But more recently, and in

Trump's, Trump has said, hey,

I don't think we

need to go that far.

We're going kind of roll

back and freeze standards

where they should be in

2020 and not continue

to show these improvements.

So that Ford then says,

hey, wait a minute,

we need to kind of