Instrument Cluster Repair – 2003-2006 5.3L Chevy Silverado (Sierra, Tahoe, Yukon, etc.)

BlueDriver:

welcome to a very special edition of our

fear no fix video series on the BlueDriver

channel today we have one that's

kind of out of the ordinary there's no

trouble codes doesn't really hurt the

way the vehicle drives it's not unsafe

it's just a pain in the butt it's when

your PRNDL indicator is not reading

out so... there's a really expensive fix

and then there's a really cheap fix

Chris this is a great one this is an

honest full-on just repair we're not

replacing any parts we're just gonna

remove the instrument cluster we're gonna

resolder a bad connection

put it back in and we're good to go yeah

this happens all the time on these

trucks so hopefully this saves you a ton

of money and hopefully this video saves

you a bunch of time and if so please

like the video and subscribe to us on

our BlueDriver Channel let's get at this one Chris

the tools you'll need to

complete the instrument cluster repair

are a ratchet, a seven millimeter or

nine thirty second socket a ratchet

extension a soldering iron and wheel

chocks

we'll start by setting the steering

wheel as low as it can go next we're

going to put the ignition run for a

second and we're going to put the

gearshift as low as it can go

now we're gonna pry out on this panel

right here from the top looks like

someone already tried this repair a

couple years ago I swear this wasn't me

just start around the edges pull gently it'll pop out

and up and out

now we're going to take a seven millimeter socket and we're gonna remove the bolts here

here up here and back there

we'll have to put the gearshift back as

low as it'll go

pull the instrument cluster out

and then squeeze in on this gray connector right here

and that's it

all right we're set up on the workbench first thing we're

gonna do is take the instrument cluster

apart and then we're gonna have a look at that board

first we're gonna ply up on these clips here and here

and the clips on the other side

push on these two tabs with a

screwdriver and then pull up

now we're going to remove the gauge

needles pry up on the needle on both

sides at the same time and pull them off

the stepper motors

these resistors here are the most likely

culprits small cracks might develop

where the resistor is soldered to the

board

this can cause intermittent display

issues or the display might fail completely

this is a close-up of the

solder joint under a microscope you

don't need anything like this for the

repair this is just kind of to give you

a good idea of what exactly is going on

you can see at the bottom of this

resistor there's a small crack running

horizontally as the resistor pries up or

down this can make or break contact

causing the display to come on and off

just to play it safe we're going to

resolder each resistor

using your soldering iron melt the existing solder then add a dab of new stuff as well

we'll do this again now for each

resistor

now we're ready to reassemble the

instrument cluster snap on the front half

reinstall the gauge needles on the

stepper motors make sure the needles

can't rotate counterclockwise beyond the

zero position for each gauge if the

needles are put on incorrectly then when

you start the truck you might see

something like 5,000 rpm negative 1,000

rpm zero volts etc so they have to be

put on in the same position they came

off

snap on the back half of the instrument panel

that's it for the repair and now we'll

head back to the truck to see if it worked

now that we've resoldered all those

resistors we're going to put it back in

first we'll hook up this connector

the gray points back towards the front of the truck

put in our four seven millimeter bolts

put the gearshift in the lowest position again

and reinstall the dash piece

and then just push all around the

outside to clip it in

now that everything's reinstalled we're gonna give it a try and see if we can figure out what gear we're in

perfect everything looks great

ah ha! and there it is it works again

nice Chris now I know when I'm in drive

my garage door is safe so this one you

don't have to clear check engine light

no nothing you're back on the road not

hitting your garage door so if you liked

this video if it made your life easier

if it saved you a ton of money please

like the video and subscribe to our BlueDriver channel and until next time

Fear No Fix

you

Here's Why Chevy Dealerships are Crap

Scotty Kilmer:

rev up your engines

Michael cologne he says 07 Acura

RDX 90,000 miles called P2263 issued a

check engine light the dealer once

replace the turbo for six grand it pulls

fine and I don't feel any difference I

can't pass inspection please help yeah

you know when you get vacuum leak or

stuff wrong with the system it won't

pass emissions testing they're trying to

say the problem is in your turbo it very

well could be but if it runs okay so

you're stuck between a rock and a hard

place find a mechanic like me maybe he

could just reset it drive it a little

and if it'll pass the emissions test

then go get it tested right away I do

that for customers all the time when he

got some nagging thing that's gonna cost

a fortune but it runs okay a lot of

times you can reset it if it's got some

kind of a vacuum leak at least just

patch it with duct tape or something you

just take duct tape up if you want as

long as it runs okay you know there's

always ways to get around stuff if four

car runs perfectly fine door somebody's

trying to rip you for that kind of money

now if you do have to replace the turbo

don't pay 6 grand don't go to a dealer

you can get refurbished ones from many

places all over the world online and

replace it with a recondition one this

places that will take yours and

refurbish it for you Greg says Scotty

is a 2.7 liter EcoBoost a good reliable

engine over time understand what

EcoBoost is it means that it's GDI

gasoline injection with insane

high-pressure spraying of fuel directly

in the engine and also turbochargers

which brings more air in the engine so

there's more pressure in the engine and

guess what the more pressure the fast or

something will wear out over time if you

took that same engine and it was just a

normal engine with fuel injection and no

turbos and drove them both in the same

vehicle the one that's the EcoBoost is

gonna wear out faster and it's just the

way that it goes strain more they're

gonna wear out faster they work fine for

you know usually the first few years

100,000 miles or more

but eventually it will wear out fast to

realize that if you're the type of

person to trade your vehicle in every

100,000 miles your style you probably be

happy with but if you want really really

long-term now you better not to buy that

complex stuff Senya treasure like says

when should I change all the fluids in my

2014 Durango Hemi I only drive 5,000

miles annually well oil it doesn't

matter its mileage and/or age so you

want to change the engine at once a year

use good synthetic oil change it once

here that's fine the rest of the stuff

you're probably gonna go more by time

than mileage like I would change the

transmission fluid but if you only

driving 5,000 miles a year I change it

once every five or six years yeah and

the coolant you go by the not the

mileage but the year like a few at that

Toyota hoat coolant that's good for up

to seven years the Dodge coolant I

believe the factory stuff is good for

five years find out how long it is and

then change it by the years not the

mileage because things wear out over

time

find out what time for each and change

it at that time instead of the mileage

because you're not putting on the

mileage they still degrade over time

specially the engine oil, J Texas 1974

live free or die Scotty can you

tell me how long you can drive a car

with a failing or bad torque converter

thanks well of course that depends on

how bad the torque converter is yeah I

got customers with torque converters

that are weak that drive them for years

and years and years in my 94 celcia has

an automatic transmission the torque

converter is weak but it was a weak when

I bought it used and it's still weak and

I still drive it the only problem with

that is it shakes a lot in drive so when

you're driving if you leave it and drive

the engine shakes and idle I just put it

neutral and it runs smooth this can be

so I Drive it that way I really don't

care I'm not gonna take the transmission

off just to change the torque converter

and if it still works like that who

cares but there are torque converters

that physically fall apart when they

start making noise or when the gears

start to slam into gear when you're

driving then they're not gonna let us

talk that long it depends on how badly

worn they are cuz they will wear in

different models in different ways some

of them just have bad welds GM had some with bad welds

when the welds break then it starts

falling apart clang and then you got to

change it sooner than later or it will

destroy a bunch of other stuff Garcia says

Scotty I was a feeling driving on GT

Mustang 65 I've been 2005 in a Celica

2002 I feel like you oh yeah yeah the

old cars the fun to drive they're real

cars that's said

they're not like a modern car you get

turn the key and take off and that's all

you got to think about stuff that's 65

GT that I was showing it's got a hand

choke you gotta start it up play with

the chock a little let it warm up a few

minutes before you drive it seriously

and you know it's a standard

transmission so you gotta shift gears

and it's an old one so that's the clutch

it's relatively stepped you got to be

used to pushing down on that hard clutch

with your left foot the only thing I

ever drove this stiffer than that was a

customer had a Corvette and that you

he had to use both feet on a

clutch pedal to get it down it was so

hard to push it down on that Corvette

they were notorious for having sticky

clutch pedals but you know it's another

experience you're actually being part of

the Machine and you feel it and you get

feedback and bumps and it's a real

driving experience you know if you're

the type of person that just wants a

smooth thing definitely get a new one

don't get it old one, station money says

I got a 07 Ford Focus that has a

pinging sound under load when I use 87

octane using 89 there's no pinging how

can I get it to stop pinging when using

87 octane you know the problem is it's

12 years old

it's just worn with the higher octane

gas I mean you're better just to use it

because all kinds of things are going on

there it's probably that your timing

belt your timing chain is worn somewhat

the engine has a little carbon in it I

mean if you want to try my advice would

be paying mechanic like me to carbon

clean your engine because if there's

carbon buildup that increases the

compression ratio and you need to higher

test gas so it doesn't ping sometimes on

those just having them carbon cleaned

then they'll run normal on the cheaper

gas I tried that burst they make the

most logical thing to do

keoki Tara's says Scotty I changed the

sway bar links on my 08 Pontiac g5

but it still rattles when I hit bumps

what could be wrong you change the sway

bar links

those are links at the end right the

sway bar itself has to hold downs they

have rubber bushings on them check the

rubber bushings they could be worn out

too but of course realize there are a

zillion things that can make rattling

noise on a suspension system jack it up and

pull on it and hope you can duplicate the

noise now if you can't I have a video

called finding the source of car noises

watch that video and with that machine

if you don't want to buy one you're

gonna use one on eBay for like 50 60

bucks or a new one 410 bucks it will

pinpoint any sound in a car but check

the bushings first you changed the

links on the end of the bushings are

worn it'll still rattle around when you

hit bumps, res says toyota oem coolant

or third party pink

acceptable it's okay to mix different

brands of engine coolant all right well I always try to use the same thing but what's

in them is what counts and from my

experience I look around all the pink

and red coolant that I've ever found was

whole coolant hybrid organic acid

technology called the new style one that

Toyota's use and as long as it's hoat

coolant you can mix them it's perfectly

fine just like any olden days you didn't

care if you use impressed on coolant

factory GM coolant whatever as long as

it was the same type the older type

coolant was called inorganic acid

technology IAT and the new one is OAT

organic acid technology and the real

fancy ones like Toyota's are Hoat hybrid

organic acid technology as long as you

keep the same oats or hoat coolant in it

it's fine you can mix them, mike says

Scotty my 2015 Mazda 3 left front wheel

vibrates at 25 to 35 but it goes away at

a higher speed what can cause that you

got sympathetic vibrations in there

odds are to be rebalanced or the tiger

might just be shot go to a good place

where they balance tires have them check

the balancing of the tire if it's off

balance that can do that or it's a tire

itself a shot that often happens when

they're made of various belt wound

around in a circle and if the belts

break internally then they're no longer

perfectly round and at a certain speed

they'll go like mad but don't want to

get spinning faster it expands out and

becomes perfectly round again so had the tire check praise just needs to be

but if the tires crap pink albino your

tire because that will do different

things at different speeds cuz it's

rubber and can stretch and change as it

speeds up it's not like a man on a solid

steel where the speed doesn't change the

shape, Steven Mayer says Scotty are you

stoned dusted sunglasses no I'm blind as

a bat if I take them off I am blinded

and I have studio lights pointing at me

so you can see me otherwise you wouldn't be able to see me all that well I put

them on I don't look as old it's a

show business thing with sunglasses on

you don't look as old but now I'm not

stoned I haven't done that stuff since

college and that was let's see 42 years

ago that's what I graduated, game says

Scotty I have a 2010 Mazda 3 the sound

stopped

I had the Bose package mechanic told me

to replace an amp or get a new radio why

are the speakers what should I do

yes when you buy a vehicle with a fancy

stereo system and it breaks often either

to get new parts hardly anybody ever

fixes them right or to replace the whole

thing with a factory unit cost a fortune

you're better just going aftermarket I

do it in all my cars because the

aftermarket stuff these days every two

years they're they work twice as well

and it cost half as much so your carts a

few years old

you put modern stereo in sounds tons

better and it costs pretty nothing

compared to the original

so do that just get another new one

research what particular ones you want

like if you don't have an android and you want to

put an android in now if you want an

Android there's good androids out there now

for a little was doing her 50 bucks

don't buy the $80 androids they stink

I've tried them out but the more

expensive ones they're pretty good

androids that are easy to wire it I got

a video on that it's it's not that hard

to do,

so if you never want to miss another one

of my new car repair videos, remember to

ring that Bell

GM Instrument Cluster Repair and Service

GM Gauge Repair:

GMGaugeRepair.com is your source for

GM gauge repair and service.

Specializing in GM instrument cluster

repair, GM speedometer repair,

instrument cluster rebuild, and entire LED

dash kits.

GM Gauge Repair uses only GM

approved

stepper motors with lifetime warranty

and same day turn around.

Visit us today at GMGaugeRepair.com.

How To Remove and Repair Chevy Stereo AUX Input Suburban Tahoe Silverado Sierra HHR

ScubaMoto:

Today I'm going to show you how to fix a

problem that's very common in some of the GM factory stereos.

I was hitting bumps on the road and the stereo would

start switching back and forth randomly

between auxiliary input mode, radio mode, and CD.

And it took me a while to figure out

that if you agitate the auxiliary plug

that's in the front of the unit, you can

repeat the problem.

So, I knew there must be a loose connection in there.

Unfortunately, it's a simple fix but we have to take the stereo out. So we're

going to need some pry bars to get this trim piece out.

The trim piece is held on by nine push-tabs.

And I'll show you their exact location in a second because if you can get your pry-bar close to

those push tabs, you'll reduce your

chances of damaging anything.

And now you've got eight 7mm bolts.

So we're going to use a 7mm socket.

And the way these head units are

put in is they overlap on the mounting bracket.

So you have to start from the bottom removing them.

And so that's what we're going to do. And I won't make you sit through all this. I'll go ahead and speed up a little bit.

Once you get the bolts off for the bottom head units,

we can go ahead and slide those out of the way. And now there are four more bolts holding the stereo in place.

And that's what we're going to be removing to repair.

And once we slide that out, you'll see on the back, there are just four plugs holding it in.

They're pretty straightforward. You've got

the antenna here. You've got the USB.

And then you've got the audio plugs. And

there's a little thumb release as they come out pretty easily.

And don't worry about what they look like because they only go in one way.

So when it comes time to put the thing back in, it's pretty easy.

And obviously that's your USB right

there. So once we get all four of these off,

we can put it in the shop where we

can work on it.

And the first thing we have to do is pull the face of the unit off. And there's just six little pressure tabs that are holding it in place.

Be careful with these you don't want to break them, of course, they're the only

thing holding it on.

And just a standard flat blade screwdriver can be used to unlock them.

And once you get those unlocked the

whole face of the unit will pop off.

This made life a whole lot easier for

removal of these screws.

But if you don't want to buy one or you don't have a mini socket I'll just show you.

You can certainly do it with needlenose pliers. It's just going to take a little bit longer for you.

And once you get the screws out, there's still four of the

lock tabs that are still holding the

back of the faceplate in place.

So, once you release those, you can go ahead and lift the back away and see the circuit board.

And I'm kind of holding it together because there's a couple of parts in there.

I'll show you in a minute, but this is the culprit this is your auxiliary plug right here.

And you can see that it's loose, but unfortunately we

can't see where it's soldered to the

circuit board yet. We need to pull this back off.

And don't be intimidated. These plastic pieces are just light plates.

They only go on one way so what they do

is they sit next to these little white powerful LEDs.

And these LEDs just fill these plates with light and the plates

distribute the light to multiple points

for your display.

And this is what one of the LEDs looks like. So once you get those out of the way you can see here

I'm going to give you a close-up. Now we can see where the feet of this auxiliary plug have broken.

And you can see the little cracks. Well, what's happening;

when that jiggles around, it's sending false signals to the controller to switch from

radio mode to CD mode. And, unfortunately, it makes a little tough for listening in the car.

The fix is super easy. As you can see, it's just a fast resolder of those

four feet that are holding it to the

circuit board.

And now we can test it. And, of course,

it's very strong.

So now we just have to put things back together. One little hint. There are alignment tabs here on the large knob.

You want to make sure that those are aligned.

And once they are, it will slide right into place. And, as I mentioned, the light plates only go on one way.

So that's a very straightforward installation. There are only three of them.

And because this whole controller faceplate plugs on to the head unit,

I'm going to go ahead and make sure those plugs are cleaned up too.

So, first we're going to snap the back on.

And you'll see that it just you can hear it snap into place.

So even without the small screws, it holds together fairly well.

But we're going to go ahead and put

those screws back in now as well.

I'll speed through this a little bit so you

don't have to sit through it all.

Okay, so the screws are all in and I'm going to clean up that main plug.

I'm just going to use a little bit of a dressing here on a q-tip. And I'm just going to clean the

plug and where the plug goes into the

main head unit.

It just gives a slightly better connection. Now we're ready to put that back on the head unit.

There are a lot of alignment dowels. Just make sure everything is lined up before you push it home.

And you'll hear it snap nicely.

Great! That looks good. We're ready to put

it back on the vehicle.

So again, we've got our four plugs. I won't make you sit through that.

Again those plugs only go on one way, so I fast forwarded through putting those on.

There's a large alignment dowel. Just make sure that you get that correct where it plugs into the vehicle dash.

And now you can put your screws back in. And we can speed through that a little bit as well.

You've got four screws that are holding the stereo head unit in.

And again, just like we removed it, it has to go a certain order.

So, we start from the top and work our

way down. So now we're getting the HVAC unit put in.

And now we'll get the head unit below that in place.

And we've got the trim piece of course with the nine tabs. Make sure you get the tabs lined up.

And then it just presses in place.

And we'll go ahead and give it a test.

It's in radio mode now. But you'll notice that as soon as I put the plug in,

it correctly goes to auxiliary input mode

and it plays music just fine.

Well, if this helps you guys out, please do give a thumbs up and subscribe for future videos.

And if you know anybody else trying to do this, please do share this video.

Thanks for watching.

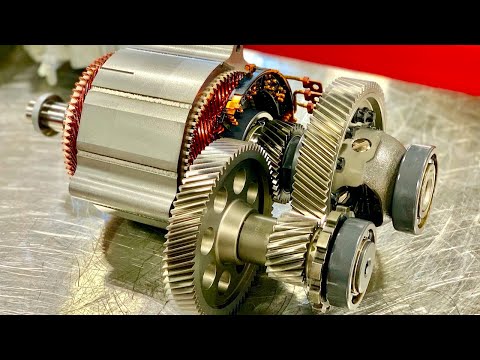

Chevrolet Bolt EV Traction Motor - Deep Dive

WeberAuto:

Hello, I'm professor John Kelly and this

is the Weber Auto YouTube channel.

In this episode we will be disassembling

the drive unit the electric motor and

gear reducer out of our 2017 Chevrolet

bolt on the hoist behind me here. now

this drive unit and electric motor

combination is is all one piece,

unlike the Nissan Leaf that has a drive

unit that unbolts from the electric

motor. This drive unit is rated at 150

kilowatts which is 201 horsepower, it is

also rated at 360 Newton meters of

torque which is roughly 266 foot-pounds

of torque.

Now let's let's talk about torque just a

little bit. That torque rating is what

the motor itself is capable of producing,

that is not the same as the torque that

ends up at the wheels of the vehicle, so

for example the Chevrolet Spark EV

produced by Chevrolet before the Bolt

here

actually had an electric motor that

produced 540 Newton meters of torque, the Bolt EV electric motor only produces

360 Newton meters of torque and so you

might be misled into thinking that the

Spark EV had more torque; well, the motor

did, but not the torque delivered to the

axles that drive the wheels. So the gear

reducer right here on the side of this

drive unit has an impact on that because

gear reduction is also torque

multiplication minus frictional losses, so

the Spark EV had a 540 Newton meter

electric motor but it only had a three

point one five to one gear reduction

unit which resulted in about 1700 Newton

meters of torque at the wheels, at the

axles. the Bolt EV electric motor

produces 360 Newton meters of torque a

whole 180 Newton meters less of torque

from the motor, but it has a seven point

zero five one eight to one gear

reduction through this gear reducer

which multiplies that 360 Newton meters

of torque by seven point zero five one

eight, which gives us over 2,500 Newton

meters of torque at the axles. So there

are other electric vehicles out there

that are being produced right now that

have higher torque higher motor torque

than the Bolt EV

but what would be interesting, I and

I don't know what their gear ratios are

yet, is to see what is the torque

actually to the axles what's the torque

to the ground because that's what you'll

feel when you step on that accelerator

pedal, that's the torque to the wheels

that makes the vehicle move. The design

of this drive unit this electric motor

it has a peak amperage draw of 400 amps

versus 450 as for the Spark EV so it

uses less current to provide more torque

so it's a more efficient better design

electric motor. The electric motor in

this drive unit spins clear up to 8810 rpm where the

Spark EV only spun up to about 4500 rpm,

and we'll take a look at some

differences in the electric motor design

and the stator winding design that

allowed it to spin at those higher rpms

without the AC losses that typically

occur at higher rpm. As mentioned in the

previous video on high voltage

components of the Chevrolet Bolt EV this

drive unit uses about 2.9 litres, around

3.1 quarts of Dexron HP fully synthetic

base transmission fluid automatic

transmission fluid. It also is cooled by

the General Motors Dexcool 50/50 mix

of coolant and deionized water. Okay

let's take a look at the outside of the

housing here of this drive unit. The

official name or designation of this

drive unit by General Motors is the

1ET25. The one means it's a one speed

trans axle, this doesn't shift, E means

it's electronically controlled, T means

it's a transaxle, and the 25 is a

relative torque rating. Alright, right

here on the front of the transmission is

the actual last eight digits of the

vehicle identification number and you

can see that MMF right there, that is

the three-digit regular production

option code the RPO code that you can

find on label in the back of the Bolt EV if

you take out the lower compartment

carpet and look in what looks like a

spare tire tub, there's a label on the

driver's side that has a whole bunch of

three digit codes on it

MMF just means that's which transaxle

or transmission this vehicle came with.

Okay right here on the top of the trans

axle is the transmission range selector

actuator and this is a brushless DC

motor with a gear reducer that actually

moves the shift lever to put us in to

Park reverse neutral Drive and low, now

technically inside of this drive unit it

there's really only park and not park,

but there is a position sensor in here

called an internal mode switch that will

monitor which position the transaxle

range selector is in so that the vehicle

can act appropriately. For example the

shifter itself on the center console is

not directly connected to the drive unit,

it's just an input to the computer that

controls this actuator, so when we go to

the reverse position for the neutral or

drive or low, there's a feedback on the

internal mode switch electrical

connector right here, that lets the

engine control module, even though this

doesn't have an engine, know which gear

range you have selected so that it can

request the trends axle act

appropriately. Also, right here by the

electrical connector for the internal

mode switch is the transmission fill

plug, so if you want to put fluid into

this transmission you need a 14

millimeter wrench or socket to take this

plug out and put the Dexron HP fluid

into the transmission. There are two

drain plugs on this transmission, one for

each side, so there's one down below on

each end of the transaxle the driver's

side and the passenger side, there's

there are two separate drain plugs to

get the fluid out of each side, now

there's only one fluid that goes

throughout this entire transaxle but

because of how its baffled and set up

inside to remove all the fluid you need

to remove both plugs.

Now speaking of fluid and fluid level

when you drain fluid at whatever the

recommended fluid change interval is or

if you're doing service work on the

transaxle here and you're adding fluid

you need to know when to stop adding

fluid, so on the other side of the

transaxle right here is the transaxle

fluid level check plug, so the drain

plugs right down here, the fluid level

check plugs here, the fill plug is on the

other side so you take the fill plug out

you take the fluid level check plug out,

and you add fluid until fluid comes out

over here, and then you let it sit and

stabilize for a minute add a little bit

more and make sure that fluid comes out

comes out to a slow drip, and then the

instructions tell us to put both plugs

back in and go drive the vehicle until

the transmission fluid temperature

reaches 35 degrees Celsius or 95 degrees

Fahrenheit and then double-check the

fluid level again to make sure that

comes out at a very slow drip. Alright,

while we are here on this side of the

transaxle we have an electric motor an

electric pump for the transmission fluid

so there's a big filter we'll see when

we take this thing apart down the bottom

center of this transaxle it will pull

fluid up from the filter and then put it

into what's called the oil sump so the

oil sump is basically just a great big

bathtub looking area up here that the

pump fills full of fluid and then there

are these little drain channels that

fluid drains down to cool the stator

windings and lubricate bearings and so

on and we'll see that once we get the

cover off so we have an electric 12 to 14

volt driven electric motor that pumps

fluid throughout this transaxle. From

what I read this pump only works when

you are in Reverse or Drive, it does not

pump when you're in park or neutral.

Alright, we have another electrical

connector right here, this connector is

for the resolver which measures the

angle of rotation the direction of

rotation and the speed of the electric

motor rotor itself, and then there's a

transmission fluid temperature sensor

that is in the bottom of this

transmission case cover here. All of

those are accessed electrically through

this electrical connector right here. As

you may have seen in my other video on

high-voltage components we have the air

conditioning compressor of the bolts up

here and then we have our coolant pipes

that go into what's called a coolant

sump in the bottom of this transaxle and

we'll see that here in a few minutes but

we have coolant going in coolant coming

back out and goes through a series of

cooling fins and cooling circuits to

absorb heat from the transmission fluid

right here on the back we have the

electrical connection for the

three-phase cables that come from the

the

single power inverter module that sits

two modules above here. Three-phase

orange cables come down to drive the

electric motor, there's a cover

the cables bolt on and then there's a

cover they'll holds the cable in place.

We have a transmission vent right here,

let's just take that vent off while we

vent tube off while we're here now you

can see the oil sump area again on the

top and the cooling sump coolant sump

area here in the bottom all right there

is one additional plug on the side of

the case with the electric motor and

there's nothing in the service

information to indicate this but I

believe this is a pressure test plug to

check the pump output pressure, but I

can't find any information on what that

fluid pressure should be. Okay, I'm going

to be disassembling this transaxle right

here on the workbench but there actually

is a special fixture to hold this

transaxle and allow you to rotate it and

disassemble different pieces of it and

still be able to rotate it for

convenience. I have this special adapter

as you can see here in this photograph

but the way it's mounted it's too high

and too difficult for me to disassemble

in that holding fixture being in a

wheelchair, so the workbench is where I'm

going to disassemble it, but I wanted you

to know there is a special fixture for

that and I tried it it just doesn't work

for me.

by the way this transaxle weighs about a

hundred and seventy pounds or 77.4

kilograms. Okay, well we're ready to

start disassembly, the first step is to

remove this oil pump the 12-volt power

oil pump, it has three bolts right here

and a few seals underneath it as you can

see here there are two seals that seal

the pump to the transmission case right

here there are two bolts that hold the

cover over the pump gears themselves

there are no instructions on

disassembling this so I assume we're not

supposed to disassemble it but that's

exactly what I like to do

take things apart I'm not supposed to as

long as I can get them back together and

make it work again here we go we've got

a Jew rotor style oil pump there's an

o-ring right here that needs to fit in

this groove to seal and then the cover

just bolts on okay the next thing on the

list is to remove the left-hand and

right-hand output shafts that go into

our differential side gears in the gear

reducer this is the left-hand side right

hand side over there it calls for a

slide hammer and a old pilot bearing

removal tool for a manual transmission

so this is the pilot bearing removal

tool right here and a slide hammer and

we are supposed to put this up inside

and put it into the snap ring groove for

the CV shaft and then pop it out well

come to find out the snap ring groove is

thinner than the tip of this tool that's

supposed to go into it and I didn't

realize that's what the problem was and

I had a hard time getting these output

shafts removed I finally got him out but

once I got a mound got looking at the

tool versus what they were supposed to

be grabbing I realized I need to grind

these down make him a little thinner so

that they'll actually fit into the

grooves of the her for these CV shaft

snap rings that are there so since I've

had this entire transaxle apart before

and I'll put it all back together

I've removed those snap rings they'll

hold these output shafts in place so I

can just pull them out by hand right now

this big long left hand output shaft

goes right through the center of the

rotor of the electric motor itself it's

it's hollow in the middle

and it has a big heavy-duty bushing

right here on the outside with the axle

seal and this is our left-hand output

shaft and then the CV shaft itself plugs

into here that goes to the left front

hub and bearing assembly and tire and

we'll assembly so there's our left-hand

axle shaft there's a snap ring that fits

in that groove right there typically and

I've just removed and I've just removed

that snap ring for ease for this

demonstration here obviously I'll need

to put that back in when I reassemble

so that's the left-hand axle shaft on

the other side we use the slide hammer

again and pull out the right hand axle

shaft as you can see this one is much

shorter than the other one and it has

the support bearing in the differential

case itself that holds it in place and

its own snap ring that I've already

removed and of course an axle sill here

on the other side as well okay the next

thing on the list is to remove this

transaxle case to remove the case I've

got to take the linkage off and our

actuator off and then we've got these

bolts to go all the way around and then

we'll be able to see the gear reduction

transfer gear and the final drive ring

gear and differential gear set so I'll

take the clip out and lift up for a

linkage on the shift actuator and then

take the bolts out

okay here's the shift actuator assembly

itself transmission range selector

actuator kind of a great big piece I

I've seen some of these that are smaller

right I'm not sure why this one is so

giant I'm not I've never seen one this

big but it obviously does the job of

mechanically shifting the transmission

range lever since you have an electronic

shifter on your center console alright

let's take these bolts out of the trans

transmission case okay I've got all the

bolts out of the transmission case now

we can attempt to slide it off it has a

couple of dowel pins they'll hold it in

place there's a couple of pry points

plus one right back here and another one

right here there we go

I'm going to come in with a plastic

mallet here and just tap lightly there

we go okay we can see inside of the

transmission case itself and the only

things in here of real interest are the

transmission internal mode switch right

here we got the electrical connector

right here harness right there that

connects to this outer blue connection

connector that will read which Range

Park reverse neutral low you have

selected with your transmission shift

lever and then we have the parking

linkage right here we've got Park

reverse neutral Drive

and low now of course normally

transmission fluid would would be

pouring out of here of whatever didn't

get drained out when you drained it

previously but I've had this apart and

cleaned everything up before we have our

ring gear right here and our

differential gear set and as notice we

have real nice ball bearings here these

bearings since their ball bearings

instead of tapered roller bearings have

to have in place shims so there's a

special shimming procedure to control

the end play of these bearings that will

have to go through when we reassemble it

so you're supposed to take these shims

off and throw them away well and then

replace them with new new ones when you

go back together I suggest that you take

them off and measure them and then hang

on to them because you might you might

need them again when I took these off

previously and measured them they were

almost all identical in the thickness so

there are six of these shims for the six

ball bearings that are in this transaxle

four of these shims measured exactly

half a millimeter in in with the other

two one of a measure one millimeter in

width and the other one measured 0.9

millimeters so you need to keep track of

what thickness shim you had where and

write those down so that you you'll have

an idea of at least what it was before

you took it apart now if you're just

going back together and you haven't

changed any shims or any parts inside

just reuse the old shims but if you're

changing a bearing or any of these

internal pieces you need to go through

the special measurement procedure that

we'll see when we go back together to

determine if these shims are correct

okay so there's there's special shims on

each of these

bearings I've measured all of them RIT

written their dimensions on the ziploc

bag here that I keep them in and will

refer to those when we go back together

all right now we just need to remove the

counter gear right here and the final

drive a ring gear and differential gear

set this is where our short little

output shaft plugged in right here and

then our long one came all the way

through on the other side okay before we

remove these gears there is a an

aluminum gasket with a rubber seal

embedded into it the instructions tell

us that is not reusable

there is also an oil baffle right down

here to channel transmission fluid away

from the ring gear to reduce losses as

it rotates into it and to splash oil up

into different channels to lubricate the

the bearings if we look in this case

half right here you can almost see what

looks like a funnel right there for the

fluid to drain back down and lubricate

this outer bearing and a similar one

here on this other other side for that

bearing so we've got a oil baffle to

remove all right I've got the oil baffle

removed on the other side of that is our

magnet for metallic particles from gear

normal gear wear and other malfunctions

okay now we're ready ready to remove

these gears pull out on the counter gear

and then pull out on the final drive and

it'll come right out if you don't pull

out on that counter gear first there's

not enough clearance for the final drive

Unit two clear so here's our final drive

you can see our open differential gear

set inside there here's our sim on the

other side as well

all right the instructions tell us that

we can if we won't want to remove the

park linkage in the internal notes which

I don't really care about that that's

just regular stuff that you'd see in any

other automatic transmission so let's

continue on with things that are unique

to the bolt

evie drive unit here the one ET 25

transaxle so let's turn the transmission

case around and we'll take off the

transmission case cover here on the

driver's side

now the SAE document the details the the

bolt evey drive unit here that I told

you about in the high voltage component

video tells us that the drive unit

itself was designed to be serviceable in

the vehicle that's why they have a case

removable case cover on one side and a

case cover on the other side for the

gear reduction unit you can leave this

Center portion with the electric motor

in it in the vehicle and just remove one

or both case covers to do service work

on components inside the case covers

seal replacements resolver replacements

internal modes with replacement and so

on but anyway we're going to take off

this case

cover next from the driver's side all

right this case cover is going to be a

little harder to get off than the other

one because the rotor that has internal

magnets embedded inside of it has now

magnetically pulled itself over to the

stator because we are no longer

centering it inside of the stator itself

and so it puts a it pulls it off to the

side just a little bit so there's a

prying

right here

and there's a pride point right down

here another prior point right here

there we go okay so here's our case

cover and it has an aluminum gasket

that's not reusable as well our case

cover has this long transmission filter

that's not serviceable without

disassembling things as you can see has

a temperature sensor down inside of it

right there and then this is our

resolver our serviceable resolver that

measures the position speed and

direction of rotation of the electric

motor rotor inside the transaxle here

let's turn this around oh by the way

down inside of the bearing housing there

is a shim for the ball bearing right

here on the rotor itself so we're

looking at the stator and the hairpin

six conductor deep stator design a

unique design we'll talk about that a

little bit more once we get the stator

out we have a lubrication channel right

here where fluid is going to drip out of

our oil sump and run along and drop down

on to the stator windings themselves and

cool the the stator windings it also has

a drip channel that comes over and goes

down to this bearing here to lubricate

it

so we've just got an 8 millimeter head

bolt holding the filter in place and as

you can see the filter just has an

o-ring seal on the one side and you can

see the pick up filter screen filter

element on the inside so this is going

to reach all the way in up underneath

the the stator itself to pick up the

fluid on the back side of it and on the

back side of it is the inlet of the

coolant so that would be the cooler oil

on the back side there all right then on

the resolver it just has eight three

eight millimeter head bolts to hold it

in place and one electrical connector

this resolver only bolts in in one

location it's not adjustable it has

automatic learn unlike the older Toyota

Prius resolvers that that would actually

come out of alignment

if you unbolted them and there was no

way for you to line them back up okay so

here is our resolver pull back on the

connector position assurance clip

depress the tab and remove the resolver

itself the resolver is a serviceable

unit when and if it ever goes bad but it

should should never go bad all right

then the remaining wire harness and the

pass-through connector here just goes

over to our temperature sensor okay next

on the list we need to remove what is

called the center support this is what's

supported the driver's side ball bearing

of our differential case assembly

okay this is our center support it's

held in place with six bolts and aligned

with two dowel pins right there now with

that removed there's nothing to stop our

transfer gear from sliding out it's just

a tight fit on the bearing in the bore

as it should be just pray lightly

sometimes these will just slide right

out and right in and other times they'll

they'll fight you here we go okay so

here's our transfer gear it's ball

bearing and shim so put that shit over

here with the others okay right here in

the end of the case we still have a

lubrication channel right here from the

oil trough the oil sump I mean right

there and then we have a cover for the

three-phase electrical connector right

here as well then on the other side we

have that oil distribution channel right

here that cools the stator so we've got

to remove that we are now to the point

where we are ready to pull this rotor

out but we just can't grab on to it and

pull it out it has some super strong

neodymium magnets multiple layers envy

configuration inside of this stator

you're not going to pull it out by hand

and you sure don't want to come in here

and start prying on it so the only way

to get that rotor out of there if you

want to remove it for service replace a

bit bearing on it or the gear on the

other side or another bearing or just

replace the rotor itself for whatever

reason loss of magnetism and trouble

code sets or whatever

it takes a special tool to pull it out

without having it rub on the stator

frame itself and without having it

injure you with you trying to pull it

out and it's pulling back in with all

its magnetic strength so true get that

out there's a special guide tool that

will hold it centered in the stator and

we need to set that up next and it

starts on the other side here so there's

a special tool kit that costs almost a

thousand dollars to Center this rotor as

you pull it out I found one on eBay for

a little bit less than that but but it's

a very expensive tool but if you want to

do service work on this transaxle you've

got to have it so let's bring in the

special tools okay so I brought in the

special tools to keep the rotor centered

there's a special spacer with a notch in

it to clear that notch right there this

is just gonna fit in there just like

that then there's a plate that bolts on

over the top of this to hold it in place

these don't need to be super tight

they're just holding that little spacer

in place so I'll just lightly Snug those

up then there's a sleeve here that's

supposed to fit down the center of that

rotor but these sleeves are a little bit

too big I've had to take sandpaper and

send them down to make them fit inside

of this rotor and I don't know if that's

because the tools were made for a first

design rotor and then they changed it or

if they just made the tools incorrectly

but these tools are from what used to be

can't more tools the special tools

supplier for General Motors it's now

Bosch service solutions so Bosch you may

want to take a look at this this tool

here the DT five two zero one one

- one - three because it doesn't fit

it's not doesn't Center up inside the

the rotor as well as it should

i've had to sand it down just a little

bit and then i'm able to tap it in a

little bit there but I think that it's

supposed to be if it's supposed to be a

tight fit but it should be able to slide

in by hand I believe then we have a

guide pin that's going to go through the

center of that then we have this outer

housing the bolts in place to hold the

guide pin in place so the blue sleeve

this one here because there's one for

the other side also centers the rotor

into this plate and then this sleeve is

centered into this plate so we've now

centered the rotor on this side of the

stator so now we need to go to the other

side to put additional tools in to get

it centered and then pull it up and out

okay at this point if I had the

transaxle mounted in that special

rotating holding fixture I would just

simply rotate it on its side and get the

get the rest of the tools hooked up but

I don't I'm not able to use that so I'm

just going to put some extra long bolts

in this side of the case to hold the

case up off of this tool when I tip it

over to support it as we pull the rotor

out

okay so here we go we're going to tip

the tip the whole thing up on its hand

just like that so now we've got

clearance for the tool underneath and we

can get the upper tools set up to pull

the rotor up and out all right while

we've got the transaxle tipped on its

side let's take this oil sump cover off

and show you what's inside of there so

it's just a big empty trough and you can

see has one two three four five six

holes in it where fluid is going to go

out and drip down on other parts inside

of the transaxle for stator cooling and

for the ball bearing lubrication the

cover itself has that same aluminum

gasket that's not reusable also while we

have this transaxle on its end let's

turn it over and take the coolant sump

off next okay here's our coolant sump

you can see this pipe right here is

where the coolant comes in and it has to

wind back and forth back and forth and

then come back out over here the coolant

sump which is visible from the bottom of

the car with the under car cover removed

also has that same aluminum gasket

that's not not reusable why are they not

reusable I don't know maybe the aluminum

crushes these I'm going to see if I can

buy replacement gaskets at the local

Chevrolet dealer it seems like I saw a

service bulletin saying that all these

parts are serviceable now and it gave

the part numbers for them but if not

none of these are damaged it only has 35

miles on it and I'll reuse them and see

what happens

okay so coolant sump oil sump so now we

are ready to pull out the rotor assembly

so to pull out the rotor assembly we

have a guide pin it's going to come in

and screw into that dowel they had a

threaded end on it all right so this

threaded guide pin did not line up

exactly perfect with the guide pin down

below I can't tell if we're just

spinning the whole thing there we go

all right it's screwed all the way into

that alignment dowel from below now we

have this tool that has three holes that

go over the holes where the stator bolts

are so we need to remove the stator

bolts next these stator bolts are not

reusable three stator bolts so we put

this tool over the top of that we want

to be very careful that we don't damage

pry lean or set anything on the stator

windings here that could cause damage to

them so we'll get that lined up just

like that now I'm going to reposition

the camera so you can see

how tall this next tool is that fits on

here all right we have two clamshell

type tools that are going to come in and

clamp down over the resolver cam rotor

there and this bearing they're gonna go

just like that except I need to split

them apart so I can get the next tool in

it says this big tall piece right here

that's going to go over and down into

our stator bolt holes so we've got this

threaded shaft we've got this adapter

right here that these little clamshell

tools are going to hook into and then

the threaded shaft with a nut on the top

of it we're going to tighten that nut

and pull the rotor up out okay so the

tricky part of giving this hooked up is

getting both of these

clamshell tools over this lip right here

so I have to loosen the nut on the top

and let it come down let me turn this

you can see what's going on

there we go okay so we slide that open

clamp the clamshells around it put this

sleeve over the top of it to lock the

clamshell in place snug up this nut to

hold the lock in place and then from the

top here we start to pull up on the

rotor itself I'm going to get

repositioned bring my chair up a little

higher here so I can reach that nut it

takes quite a bit of turning to pull

that out okay here we go thirty

millimeter wrench we want to turn the

nut and prevent the shaft from turning

so I'm just going to hang on down here

as it comes up those guide pins the

guide dowels keep it from rubbing on the

stator frame although although there's

almost a strange ratcheting sound as I'm

pulling this out that makes me think

it's barely contacting the the stator

laminations or the rotor laminations

anyway we'll pull it out and take a look

see if we can see any witness marks you

can see the top of the rotor now is

starting to appear

I think we're finally clearing the top

of the yes we are it all of a sudden got

real easy to turn the nut so we no

longer have the magnet pulling out or

resisting us pulling out okay you can

see the entire length of the rotor here

get another bearing down below it and a

gear below that now we're supposed to

just lift up on this and and pull it out

I'm not sure if I'm strong enough I may

have to bring in the the engine hoist to

pull it out of here but it's just

sitting on these three non-magnetic

aluminum poles here and we've got the

weight of the the rotor assembly itself

I measured it earlier but I can't

remember what it is at this moment but

let's see if we can lift this up and out

though I cannot so let me get the engine

hoist we have to lift it up high enough

to clear that alignment dowel so I've

got to lift it up probably four more

inches 100 millimeters or so okay I've

never tried this before it's just a lift

strap let's bring it up

okay the lifting or the tool was getting

stuck in one of the holes for the the

stator bolts there we go

okay here we go

and we've cleared the alignment dowel so

slide the case out of the way here and

we'll let that back down

oh let's see how much that weighs it

says it weighs 60 pounds with the tool

the tools probably 10 pounds of that

okay we have to remember that this rotor

is highly magnetic very strong eight

pole magnetic field around this thing

and so we need to keep it away from

anything any metal particles or any

tools or anything else that could cost

cause it to receive damage on its

laminations here in looking at the the

laminations from removing it I don't see

any obvious damage at all there let's

let this down and take the the tool off

and just look at the rotor itself

little clamshell pieces out of there

these tools are magnet earth iron some

some sorts so we got to keep those away

from the magnetic field as you can see

these blue bars are aluminum they're not

sticking to the the rotor itself and

then plastic of course works great with

the magnetic fields so now we've just

got our rotor we've got our drive gear

down here I've got a ball bearing and

another ball bearing there's another

shim down inside the case a bigger

diameter shim for this bigger diameter

bearing all right I'm going to get some

wooden blocks to put this in all right

here's the rotor for the bolt

evie as you can see this bearing seems

to have some sort of a gray coating on

the outer race where this one does not

and on the counter gear bearings they

also have this gray coating it doesn't

say anything about what that gray

coating is for I suspect it's to prevent

corrosion from the dissimilar metals

with possible induced currents going

through them with the the motor running

vehicle going down the road I've seen

this type of coating on universal joints

in universal joint caps universal joint

caps bearing caps in an aluminum

driveshaft the same color I don't know

if it's the same material but if any of

you know what this coating is for if

you'd please put that in the comments

below I'd appreciate that

I'm just speculating okay so we've got

the rotor out of the way this is a

serviceable piece now the last piece to

remove is the stator assembly itself and

it has three special guide pins that go

into the stator bolt holes and screw

into the transaxle case and then they're

tapered on the top here and that's to

allow you to slide the stator out

without it binding inside so I'll slide

that over there rotate it down and just

pull out slightly

here it comes just like that so here's

the stator for the Chevrolet bolt Eevee

if we zoom in close and look at the

stator windings you can actually see

there are 1 2 3 rows of these hairpin

conductors which means they are 6

conductors deep in this stator and from

what I read in the SAE document on this

new improved motor that helps reduce the

AC power losses at the higher motor rpm

a typical stator like in the previous

Chevrolet Volt had 2 rows instead of 3

so they were four conductors deep in the

Chevrolet Volts and six conductors deep

here and one of the people that was on

the original design team for the

Chevrolet Volt told me that when they

designed this electric motor and it's

designed for maximum efficiency and hand

power that there was no other motor out

there that could even match the

efficiency of this motor and they said

that they designed this motor to be the

next small-block Chevrolet so to say of

power trains so the small-block

Chevrolet was and still is a very

popular very powerful v8 engine and has

been for many many years and their

intent was to have this motor design

maybe even this drive unit be in

multiple platforms with the same high

power high efficiency motor system if we

look at the other side here of the

stator windings you can see the the

other end of the hairpin conductors and

then there's a drip channel right here

for oil to come out of that oil sump and

to drip down and go down and lubricate

the stator windings because these get

really hot this is the heat source

inside of the transmission and it and

although it gets hot it doesn't get as

hot as the fluid

although the fluid gets hot it doesn't

get hot as a normal planetary gearset

style automatic transmission and the

cooling system surge tank reservoir cap

was only pressurized to 5 psi for this

loop of the cooling system so much lower

amounts of heat compared to an internal

combustion engine with a torque

converter heat generating planetary

gearset style of automatic transmission

now just a couple of things to get

wrapped up with this disassembly video

because we will reassemble it showing

the special measurements for the shims

and everything when we go back together

but one thing I wanted to show you about

these electric vehicles is how simple

they are and when I mean when I say

simple I don't mean simple design

meaning it was easy to design these

simplicity is not necessarily easy but

if we look at the number of rotating

parts in this entire drive unit

there are basically three main rotating

parts we've got the rotor assembly that

then turns the counter gear right here

that then turns the final drive three

pieces no clutch packs no bands and no

sprags no roller clutches no Pistons

none of those hundreds of parts that you

would see in a typical automatic

transmission let alone the internal

combustion engine that this is replacing

of course there are three main moving

parts these pieces here but each one has

two bearings on it so there's six more

pieces so there's nine total and then

inside of the differential here we have

two side gears and two differential

pinion gears so that makes for a total

of 13 possible moving parts inside the

of this drive unit and only when you're

turning corners would the side gears in

the differentials

be rotating at a different speed than

the differential case so a real basic

very reliable system these electric

vehicles and and this one is is very

efficient and that the design is very

compact to where this left-hand output

shaft remember goes right through the

center of the rotor instead of being

offset like on the the Nissan Leaf and

other electric vehicles out there so

congratulations to Chevrolet and the

design team that came up with this

amazing and efficient and simplistic

evie drive unit and I think it's

absolutely beautiful so coming up I hope

to shoot a reassembly video with all the

measurements for this drive unit and

then we've got all of these parts out

the drive unit all of the electronics

and our and our Chevy bolt back here on

the hoist is totally empty yeah under

the under the hood so we've got to put

that all back together and and make it

work again even the battery is out the

whole thing is stripped as far as the

powertrain is concerned and we're gonna

put that back together and and make it

work and hopefully get it converted to a

DC fast charge thank you for watching

How To Replace O2 Sensor 07-13 Chevy Silverado

1A Auto Parts:

Here’s Why Chevy Silverados are Crap

Scotty Kilmer:

rev up your engines

GM has a lawsuit against them now saying

that they were selling diesel pickup

trucks in the United States they

couldn't run correctly on American fuel

it turns out that a bunch of them had

Bosch German fuel pumps refined slightly

differently so people are saying that

it's wearing the fuel pumps out the fuel

pumps are throwing metal shavings into

the fuel injection system and destroying them

of course GM denies all this stuff I

mean they seem to deny everything they

denied that ignition switch thing where

they even changed the number of the

ignition switch replacement parts so

people wouldn't notice that the old ones

were designed wrong and then they got

sued and then they had to pay out a

bunch of money for that stuff that they

were doing and now they're claiming that

oh no that's not the case well I mean if

people are having problems what only

time is gonna tell us what happened I

think it's got the interest soon yeah

they couldn't even design their own fuel

pumps they're buying the German fuel

pumps and they didn't even probably

think before they put them in the vehicles,

jackie says Scotty what would be a

great first car for about two grand if

you want reliability get an old Corolla

or an old camry,

now for two grand its odds are it's

gonna be pretty old you don't get much

for two grand these day two grand today

is equivalent to when I was a kid to a

hundred dollar car and usually can't get

much for a $100 car, do the old trick

that I've always told people do you're

gonna pay that much money for a car get

one with a paint's peeling off they

don't have any value when the paint's

peeling off and then if you really care

go to one of those places like Earl

Scheib that'll paint a car when they're

gonna sale for 250 bucks or one that's

got bashed in founders it still works

good but when they look bad to go for a

lot less money, sing says

all wheel drive or front wheel drive or

rear wheel drive for a winter all-wheel

drive works better than waiting at all

the wheels driving but do you really

need that much as an example my mother's

92 she still lives in Agra Falls she

drives two Toyota Corolla front-wheel

drive car in the snow doesn't you put

snow tires on they plow the roads in

Niagara Falls and she never has any

problems now if you going skiing and

mountains and stuff all-wheel drive is

much better

front-wheel drive is pretty good and of

course rear-wheel drive is the worst for snow

you spin around it turns out that

vehicles are more controllable if you

pull them rather than push them so with

front-wheel drive you got better snow

control and rear-wheel drive because

you're pulling instead of pushing but if

you live where they plow the roads you

don't care one way or another most guys

are front-wheel drive these days anyways

clam dick said why shouldn't you use

full synthetic on an engine at state

semi synthetic 97 Ford Puma you could if

you would have from the very beginning

but my advice to people and I engineers

have argued this back and forth with me

but I don't care I've seen it happen you

have an engine that you've been using

regular oil or semi synthetic oil and

you switch to full synthetic oil and

it's been using the other oil for a long

time a lot of times they'll either start

burning or leaking oil because the full

synthetic oil flows better it's thinner

and a lot of times it'll leak or burn a

lot sometimes the engines start making

noises if you start it out with it you

generally don't have that problem but I

would just leave it alone today if you

want to buy a new car and put full

synthetic go right ahead but don't

switch after it's had a hundred thousand

miles of some other type of oil,

Jacob Roger says Scotty I got a 98

Chevy s10 with a locked up 4 cylinder

can it be unlocked if your engine's

locked up it means it has internal

problems and odds are you're gonna have

to take it all apart and rebuild it or

that old clunker try to find a used

engine from a junkyard and put in it if

you want to try you can get a long

extension bar in a socket put it on the

front crank pulley bolt try turn it back

and forth and back and forth and if you

can break it loose say take the spark

plugs out and put oil in them leave the

spark plugs out with oil in the holes if

you can break it loose maybe you can get

it running again who knows I've done

that some times in the past

Donald says how often should you change

brake fluid love your channel all your

information and tips I personally have

had Toyotas that had 250,000 miles on I

never changed the brake fluid and never

had to change anything but the brake

pads the cylinders didn't leak but on

the other hand if you got some piece of

junk like a Chrysler

I changed the fluid none have them every

four or five years they're not made that

well and they will absorb a lot a lot of

a prett have problem if you really want

to see if yours is any good there are

tests that we make

do we have little machines a test for

the percentage of water in them and the

percentage of copper because a lot of

times the copper from the lines will

infiltrate into it it won't work as well

so it can be tested if you got an honest

mechanic he can tested for you tell if

it's good or not

Rossler go says Scotty my 2010 corolla

tire spin when I hit a bump okay if you

get spinning tires half the time it's

just the tires are worn out or they're

crappy tires if you buy crappy tires if

the rubber isn't soft enough it's too

hard it will actually spin you hit a

bump and hits and it spins because it's

too hard and it slips you want to have

tires that are reasonably soft so they

grip if you're watching those car races

you might think tires in those car races

they're changing them every 110 miles

cuz they're so soft and they're going so

fast that they just erased themselves

going around a track at that speed and

at that temperature

you don't want tires that last 150 miles

but you don't want really hard ones to

skip check the tires first if it's not

the tires generally it's the shocks wearing

out and then they're bouncing and

slipping after you hit a bump, Jeremy

says what do you think of body kits well

if you wanna make your car look tougher

go ahead and bolt or not it doesn't you

know generally affect how they run or

anything problem I see with them I see a

lot of kids that put body kits on these

Honda Civics they put them way too low

and then the pieces get ripped off every

time to go over a speed bump or they hit

something and pieces come flying off,

do whatever you want it's your car I

personally think hey the way they're

made is good enough for me there are

transportation devices you know and

motorcycles generally my thing with them

is naked take everything off of them

except the motor and wheels so I don't want

anybody on them at all

so if you never want to miss another one

of my new car repair videos, remember to

ring that Bell

2006 Chevy Aveo Repairs

Easy Auto Repairs:

This is my 2006 Chevy Aveo and it just

clicked over to 54,000 miles. Its still in

nice condition. We been doing a little

work on this car come on Bryant let's

show them the engine.

Our valve cover gasket went out and no

one (at the garage) told us about it. We took it to a shop

they didn't diagnose the problem correct

two times. And it was a winter time and it

was too cold for us to get out and work

on it. That's why we took it to the shop

and we drove it just a little too far

with a bad valve cover gasket and ended

up messing up the catalytic converter

and it blew out the EGR housing and it

blew the EGR tube out. We had to replace

all of that. And here lately we've been

working on the car and

we replaced these two hoses. The main

hose off the intake. This hose here they

were like $11 for both of them. And then

this hose here went bad on us. Its these

little connectors right here, they break.

And they get old and break all of these

connectors did that. And If your car you're

pressing gas on your car won't go

anywhere replace this one. You get a code

saying your intake manifolds bad. Check

this hose right here and the EGR hose (tube).

This makes the second one that we've had

to replace. And if this got cracks in it you

can smell exhaust really bad. If this

gets us crack in it over here. So your

nose can be your best friend. To tell you

if there's exhaust coming from around

this area suspect this EGR tube. But yeah

we got to run a really really good now.

hopefully will stay that way for quite a

while. And she's purring like a kitty cat.