How Chevrolet Started, Grew & Became $11.5 Billion Company

Success Secrets TV:

How Chevrolet Started, Grew & Became $11.5

Billion Company

The name Chevrolet originated from a Swiss-born

American racer Louis-Joseph Chevrolet, who

founded his company with William Durant in

1911, stayed for four years and then left

his own company to Durant in 1915.

The Chevrolet Company previously called the

Chevrolet Division of General Motors Company

and simply called the Chevy is the automobile

department of General Motors, a manufacturing

company in the United States.

How Chevrolet Began

Twenty years before Chevrolet, Durant was

the founder of a successful Durant-Dort Carriage

Company which manufactured horse-drawn vehicles.

And so Durant wouldn't even touch a car with

a ten-foot pole, let alone allow his daughter

to ride in what he called, "loud and dangerous

horseless carriages."

But as time passed he realized that there

were more cars than carriages on the American

streets; an experience that did not settle

well with the relatively tentative public.

As the government regulated cars for their

safety, Durant had other ideas.

Why not improve the security of these cars

instead?

In 1904, Durant approached a struggling Buick

Motor Company and became its controlling investor.

Within a span of four years, Durant demonstrated

his salesman attitude and transformed Buick

into a leading automobile name amongst the

likes of Ford, Oldsmobile, and Cadillac.

For Durant, however, it was only the start.

Durant figured he could further improve his

odds in the industry if he built a holding

company that would control several automobile

divisions, with each division manufacturing

their own car.

With the Buick's outstanding profits, Durant

had sufficient capital to found the General

Motors Company in 1908.

A year later, General Motors acquired several

car brands like Buick, Oldsmobile, Cadillac,

Elmore, and others.

Unfortunately,Durant got so carried away in

his "automobile acquisition crusade" that

GM suffered cash shortage with their sales

losing to Ford's.

And so, in 1910, General Motors showed Durant

the exit door.

But Durant did not give up.

Having regained his bearings, he reunited

with an old colleague from the days of the

Buick motor company, Louis-Joseph Chevrolet.

Durant knew the Swiss-born American as a man

whose competency for car mechanics matched

his passion for racing.

In 1909, Louis had participated in the Giant

Despair Hillclimb.

An oddly apt name, considering the Hillclimb

race was less about the racers themselves

and more about test-driving the competing

car brands they drove.

Therefore, when Durant offered a chance to

build more automobiles, Louis couldn't resist

signing his name on the dotted line alongside

Durant's.

In 1911, Louis co-founded the Chevrolet Motor

Company with Durant.

Durant used Louis’ racing status as a means

of building a motor company, and his way of

getting back at General Motors.

The first Chevrolet car, the Series C Classic

Six was designed by Etienne Planche with directions

by Louis.

The prototype was ready before the company

was incorporated even though the production

didn’t happen until 1913 where it was introduced

at an auto show in New York.

In 1914, Chevrolet redesigned its logo.

And so a "bowtie emblem" logo was used on

Chevrolet’s first produced cars in 1914:

the Chevrolet H series and L series models.

That same year, Durant and Louis argued about

their differing intentions for Chevrolet’s

future car designs.

Durant wanted simple and affordable cars that

would surpass those of Fords.

On the other hand, Louis preferred playing

it fast and loose, with luxury or racing cars.

These differences split these two associates

and Louis sold his shares of the company to

Durant.

Now alone at the helm, Durant was able to

focus on his next winning car design.

He achieved this in 1916 when the cheaper

Chevrolet Series 490 finally outpaced Ford

in sales and cemented Chevrolet’s place

among the big automobile names.

To say Chevrolet made huge profits during

this period would be a severe understatement.

Durant revisited General Motors as a controlling

investor, purchasing their stocks, which gave

him the leverage to launching himself into

leading General Motors once more.

By 1917, Durant had become the president of

General Motors.

All was right, now that Durant's "big automobile"

dream was back on track.

And of course, his first directive was merging

the highly successful Chevrolet into the parent

company General Motors as a separate division.

How Chevrolet Grew

In 1918, Chevrolet launched a new V8 powered

model, the Series D for open two-seat cars

and the touring cars that could seat 5 passengers.

These models didn't sell well though and they

were scrapped by the next year.

Given Chevrolet's successful track record

in the market, General Motors rebranded and

sold their commercial grade cars and trucks

as Chevrolet with similar appearances with

the Chevrolet’s vehicles in 1919 from Chevrolet

factories located in Flint, Michigan.

The automobile company built several branch

assembly plants in New York, Ohio, Missouri,

California, Texas, and Canada.

Somewhere between the 1920s and 1940s, Chevrolet

would see Durant's vision for "producing simple

and affordable cars" come true.

In fact, Chevrolet, Ford and Plymouth were

known to Americans as "the low priced three".

During this period, one of Chevrolet's most

notable cars was the Stovebolt introduced

in 1929, which was tag-lined "a six for the

price of four".

This and several generations of the car model

blew away the competition of Ford and Plymouth.

In 1953, the Chevy Corvette, a sport’s car

with two seats and a fiberglass body debuted

to become the first mass-produced sports car

in the United States, championing the "America's

Sports Car" appeal.

The appeal of the Corvette and other Chevrolet

passenger cars would be enhanced with the

first-time introduction of Rochester Ramjet

fuel-injection engine as a high-performance

option for the price of $484.

The Chevrolet small block V8 car design made

its debut in 1955 and remained in circulation

longer than other mass produced engines around

the world.

Modifications to the V8 engine including the

aluminum block and heads, the electronic engine

management and the port fuel injection gave

birth to the designs in production today.

In 1958, Chevrolet introduced the Impala series,

which went on to become one of the best-selling

American cars in history experiencing popularity

during the 60s and 70s.

The parent company General Motors introduced

Chevrolet to Europe in 2005.

With rebranded cars manufactured from the

General Motors branch in Korea acquired Daewoo

Motors.

The economic depression between 2007 and 2010

hit Chevrolet hard.

But the road to recovery began in 2010 with

the introduction of fuel-efficient cars and

trucks to compete with foreign automobile

manufacturers.

Within the same year, Chevrolet introduced

the plug-in hybrid electric vehicles, Chevrolet

Volt in America, which was sold under the

name Opel/Vauxhall Ampera throughout Europe

with a record 5,268 units soldand became the

world's best-selling plug-in hybrid electric

vehicle (PHEV) car in 2012, winning the award

for the North American Car of the Year, European

Car of the Year and World Green of the Year.

The series was then named the combined Volt/Ampera

that was sold across the world.

It exceeded the 100,000 unit sales milestone

in late 2005 and eleven years later the Volt

family of vehicles had become the world's

best-selling plug-in hybrid as well as the

third best selling electric car after the

Tesla Model S and the Nissan Leaf cars.

In 2011, Chevrolet set a global sales record

of 4.76 million vehicles sold worldwide

In late 2013, the Chevy brand was withdrawn

from Europe by General Motors leaving the

Corvette and Camero lines.

In 2016, Chevrolet unveiled the first affordable

mass-produced all-electric car the Chevrolet

Bolt EV.

This car too has won several awards.

Where Chevrolet Is Today

Chevrolet now has its headquarters in Detroit,

Michigan, and operates throughout 140 countries

in North and South America, Asia, Australia,

South Africa, and Europe with over two million

vehicles sold annually in the US alone and

a brand value of $11.5 billion.

Thank you very much for watching our videos.

We’ll like to give you another interesting

video for you to enjoy next but before then,

our team will be very happy if you can like

this Video and share it with your friends

on social media.

If you’re new here, don’t forget to subscribe

so you won’t miss other interesting videos

like this.

Look at your screen now to see two other videos

we handpicked for you to enjoy next.

We love you

HISTORY 🚗 U.S. Automotive Industry (Automobiles Documentary)((ENGINEERING AMERICAN CARS & TRUCKS))

HOT ROD 100:

HOT ROD 100 Presents...

History of the U.S. Automotive Industry

Why GM Failed In India

CNBC:

Over the last 20 years, the

Indian automotive market has grown from

about 500,000 new passenger cars,

hatchbacks, sedans and utilities to

about 3.5

million in 2018.

The market has an expected compound annual

growth rate of about 5 to

6 percent over the next 10 years.

But, some automakers have struggled

to make it work.

Among them is General

Motors, the largest U.S.

car company. GM stopped selling cars in

India in 2017 after years of

declining market share.

It's a striking move for GM, which

in recent years has also closed

shop in other regions around the

world, as leadership focuses on

maximizing profits and making investments

in new technologies such as

electric power trains

and mobility services.

With a population of more than

1 billion people, India is becoming

one of the world's

largest automotive markets.

The country is poised to surpass

Japan as the world's third biggest

new car market in 2021.

So while there is ample

opportunity for automakers, the Indian

landscape has been particularly difficult

to navigate, especially for

American firms. GM watched its share

of the Indian market erode

steadily over several years, bottoming out

at about one percent in

2016 just before the

automaker pulled out.

So if the Indian market is

growing, why did GM struggle, especially

when GM has been

so successful in China?

To be fair, quite a few automakers

tend to have difficulty in the

Indian market. First of all, India

is a massive country with a

diverse population of roughly 1.3

billion people.

India, I think, we are

definitely a complex market.

The income levels

are quite heterogeneous.

We are divided, actually into

urban India and rural India.

The consumer requirements are actually

different even the needs are

different in both these markets.

There are a few criteria a

mass market automaker ought to meet.

They are fuel efficiency, resale

value, proximity of service stations

and the affordability of parts

and low servicing costs.

I think first thing is price.

We are a country with a

very low per capita income.

Indians are very price sensitive.

But price is not the only factor.

So now the customer also needs

some more value, for example, with

styling elements. And then, I think,

the consumer also wants a global

brand. They want a

brand which is aspirational.

The consumer wants an overall combination of

all P's, you know it may

be product, it may be

price, it may be positioning.

Which makes the things

quite complicated for OEMs.

These might seem pretty attainable,

but many automakers have

struggled to meet these

in the country.

There are a couple of companies who

have managed to crack that code

and there are several more with shares

of the market ranging in size

from small to smaller.

By far, the most successful automaker

in India is the Japanese firm

Suzuki, which alone owns

half the Indian market.

Suzuki has enjoyed something of

a first mover advantage.

It was the first major automaker to

enter India, and it did so

through a joint venture

with Indian manufacturer Maruti.

Suzuki also specializes in highly

fuel efficient vehicles, which are

extremely important in

the Indian market.

After Suzuki, Korean maker Hyundai is

the second largest with 16

percent of the Indian market.

After that, Indian, Japanese and Korean

makers such as Honda, Tata,

Kia and Mahindra all more or less

have equal degrees of market share.

Kia in particular, is a relatively

late coming brand that has been

able to succeed in India.

I think an excellent example is

Kia Motors which recently entered, it

was a new brand and

they gave a great proposition.

They were in an SUV segment and

I think suddenly right from the month

one, we saw a great success

for this OEM, in India.

Then the remaining 10 percent of the

market is made up of others such

as Ford, Renault, BMW and Nissan.

Early on, GM entered the India market

with its Opel brand, a mass

market brand GM had

owned in Europe.

While Opel cars tended to be

affordable, they failed to resonate with

Indian buyers.

I think later on they realized that's

not a brand which is really

going to work well in India because

that was not a value proposition

which they were offering

to their customers.

But then GM introduced its Chevrolet

brand to the country, which

brought it more success.

It was a great success.

They launched a few great

products like Chevrolet Cruze Chevrolet

Beat. They had that start which

they were really looking forward.

Despite these efforts, the automaker had

trouble taking share in the

Indian market. It was the first

automaker to introduce a diesel fuel

powered car of its size.

At the time, the Chevrolet beat

was the smallest diesel powered car

customers could buy in India.

It was a strong proposition and

benefited from a government subsidy

on diesel engines.

But in the end, the

diesel Beat had few takers.

The company may also have made a

misstep by trying to introduce a

low-cost vehicle GM manufactured with

its Chinese partner SAIC called

the Chevrolet Sail.

Their plan got derailed with the

introduction of Sail because I think

they underestimated the consumer aspiration

and then, I think, the

decline started. GM also fell victim

to a kind of self-reinforcing

cycle. One challenge it struggled with

was the lack of an adequate

dealer and servicing network.

More premium brands such as Mercedes

and BMW often attract customers

with the means to travel

further for service and sales.

But, mass market brands such as

GM's Chevrolet are targeting middle

class buyers who value convenience.

Dealerships in India often sell a

single brand so GM's low sales

volumes meant a single dealer might sell

only a handful of cars in a

month and risk taking losses on

the costs of running the business.

In the end, such low market share

made it difficult for GM to justify

maintaining a presence

in the country.

The automaker officially stopped selling

cars in India on December

31, 2017.

GM told CNBC it explored many

options for its India business, but

ultimately withdrew after it

determined the increased investment

originally planned for the country would

not deliver the returns of

other global opportunities.

It continues to operate services

for existing Chevrolet customers in

the country. In September, the

automaker entered a long-term

partnership with Tata Consultancy Services,

which will do engineering

design for GM vehicles meant

for markets around the world.

The move out of India was part

of a larger pullback GM has been

making around the world as

it restructures its business.

We're seeing other automakers follow

suit as they're pruning.

They're pruning the dead branches and

focusing on where they can be

strong. For GM, this is a huge shift

because GM of old used to be all

things to everyone everywhere.

And, it has now decided that

is not the proper strategy.

The automaker told CNBC if it doesn't

see a clear path to leadership

and long term sustained profits in

a particular market, it will look

at opportunities to focus its resources

on areas that will lead to

the greatest results. It added that this

is the same approach it has

taken elsewhere.

The automaker also sold its

European operations to French carmaker

PSA in 2017.

At the time it pulled out of India

GM had two factories there, one in

the Gujarati city of Halol

and another in Talegaon.

The Halol plant was acquired by

MG Motor, the once famed British

brand now owned by Chinese

automaker SAIC Motor Corporation.

GM has a joint venture with

SAIC to produce cars in China.

Reports surfaced in November 2019 that

SAIC is also in talks to

acquire GM's Talegaon plant, along

with fellow Chinese automaker

Great Wall. GM told CNBC it

is exploring strategic options for the

plant. The move out of India was

a retreat for GM and for American

auto industry. Ford is starting

to do the same.

It's trimming some

of its offerings.

Global economy and global auto

market is slowing some.

Certainly true here in the

US, it's true in China.

There's just not enough money to

go around to every single market,

too every single vehicle line.

Look at Daimler and BMW,

they've announced major employee cuts.

But in some ways it might

have been a shrewd move.

The other thing that is happening

in the market that has never

happened before is we are on the

verge of massive disruption of the

industry. You know, we're going to

have a future of electric

vehicles, autonomous vehicles and new

ways to acquire personal

transportation and now

mobility service.

There's all kinds of things.

Nobody knows when that's going to happen

or how it's going to happen,

but it's requiring a

lot of investment.

Companies like GM just can't keep putting

a ton of money into the

future as well as a ton

of money in today's stuff.

While analysts do expect the

Indian automotive market to continue

growing in the foreseeable future, it

did hit a slump in 2019.

Maruti Suzuki sales were growing

until February 2019, but have

slipped every month, year

over year, until October.

Suzuki said in November that the slowing

Indian market was one of the

factors behind the company's falling overall

sales and net income in

its second fiscal quarter.

So I think right now the

market is going through turmoil.

Our economy is struggling and if

we only talk about the automotive

market we are talking about a decline

of minus 14 percent in 2019

calendar year light vehicles.

So obviously this year is the

kind of degrowth happening, which has

not happened in last

two decades, in India.

2020, we are just talking about a

kind of a flat growth but then

going forward, in 2021, '22, '23,

the assumption that our economy

should be back, you know, the

GDP growth rate will start growing

above seven percent. Indian

automotive analysts note the country's

auto industry has to contend

with the relatively recent rise of

mobility services such as ride

hailing. The potential of these

competing technologies is still

unknown, but could affect how

interested in car ownership Indians

remain in the future.

In the end, GM did make some of

the right choices when trying to go

into India. GM was right in

terms of localizing their products

typically for the Indian market, making

it, in line with the taxation

because they were able to save tax.

But, at the end of their day, were

really not able to match with what

the competitors were offering.

If the Indian economy picks back up,

GM may find itself trying to

profitably re-enter the country.

GM's rival Ford, which has been in

India since 1995, said in October

2019 it will create a new

joint venture with Indian manufacturer

Mahindra, which Ford said will help

it develop new products faster

and drive profitable growth.

Chevrolet

Audiopedia:

Why General Motors Left Europe

CNBC:

In 2017, General Motors,

the largest U.S.

automaker with brands known around the

world made perhaps one of

its boldest moves in its history.

It sold its European Opel and

Vauxhall brands to the French

automaker PSA known for brands

such as Peugeot and Citroen.

It was the end of an era

for GM which had first ventured into

Europe nearly 90 years before.

It also marked the end of nearly

two decades of losses for the

brands under GM's stewardship.

GM executives said the deal

would unload a difficult and

struggling business and allow the company

to focus on its more

profitable North American market and free

up cash to make needed

investments in new technologies such

as electric cars and

autonomous driving.

But the move came with risks.

The European new car market is about

as large as that of the

United States and leaving it would

not only hit GM's volume but

also increase its exposure to the

ups and downs of the U.S.

auto market.

The sale of the unit

also racked up huge costs.

GM took a $3.9 billion

loss in 2017 owing

mostly to the $6.2

billion in costs it had to

shell out for the sale.

So why did GM leave?

Did the automaker simply

screw up or fail?

Was it wise to get out of Europe?

And what does it mean for GM's

future and the future of the auto

industry?

The decision actually says a lot about

how difficult it is to be a

global automaker today and the

sometimes subtle ways markets

around the world increasingly favor

local players who can tailor

their products to

specific markets.

In the end GM may have failed

in Europe in part because it just

isn't European.

The numbers show General Motors was

having a rough time on the

continent in the nine years or

so before the divestiture of GM's

European business.

It bled money at the EBIT line

every single year for a total of

about $14 billion in

losses on $208.4

billion dollars in sales it's nine

year weighted loss of 6.9

percent.

EBIT stands for earnings before interest

and taxation and is the

metric GM uses to report

the money its international business

divisions make.

Its worst year during that time

was during the financial crisis in

2009.

Where GM incurred a 15

percent loss of $3.6

billion dollars.

The best year in that period was

2016 where it still had a 1.4

percent loss totaling

about $257 million.

Now that sounds like an improvement

and in absolute terms it was.

But consider that over the same

nine year period GM turned a

profit in North America of

$28 billion on $823.7

point billion in sales.

That's a nine year

weighted gain of 3.4

percent an automaker generally tries to

target an 8 percent EBIT

for any given region and for

the world as a whole.

GM's rival, Ford for example has an

8 percent EBIT target for its

European business.

The automobiles never really

sold well with consumers.

And one of the reasons they

weren't able to achieve profitability

is because what they did sell

were primarily passenger cars and

not the higher margin trucks and SUVs

that they saw a lot of in

the U.S..

So that's that's a

big part of it.

There's also a lot of headwinds that

they faced on the cost side

of the equation with with the

cost of labor, unions, and

also more stringent regulation

particularly from an emissions

standpoint.

So a lot of those reasons are

why they had such mixed results and

from a market share perspective when

they pulled out they were

they only had about 6

to 7 percent market share.

So it wasn't really a

dominant market for them.

And GM was losing ground

during that time to competitors.

Consider that the automaker

had a 9.3

percent share of the European car

market in 2008 but that fell

below 7 percent in 2014 and stayed

there for two years and then

fell again to around

6 percent in 2016.

Meanwhile European competitors seem

to be faring better.

And once GM sold off its

European business its earnings shot up.

The automaker earned a

global EBIT of 9.9

percent in 2017 and 8.4

percent in 2018.

But why was GM struggling in Europe

when it does so well in the

United States and is

even leading U.S.

automakers in China a market that is

by no means easy to do

business in.

One reason is that

Europe is pretty unique.

To be fair to GM it is not

the only automaker that has had trouble

there.

American cars have never been an

easy sell in the European market.

Ford for example has dialed back

its presence in the region.

Gm is not alone

in their struggles.

You see Ford pulling out of

Europe and American cars just never

have really sold very well there.

That market is really dominated

by the big three German

manufacturers and others.

But it's also a

fairly fragmented market.

So they just really were never

able to compete and consumers just

didn't really like their cars.

There were larger economic and political

factors such as the great

recession and tightening emissions

regulations that made it

tougher for companies to

do business there.

Another factor is the

distinctiveness of European tastes.

At the time GM CEO Mary Barra

said 80 percent of the vehicles in

the Opel portfolio didn't share

parts or platforms with those

sold in any of

GM's other markets.

When we look at the portfolio

going forward from a vehicle

perspective or a portfolio perspective

only 20 percent of the

portfolio overlapped with the rest

of the General Motors

portfolio.

So we think the real opportunity

for PSA is to leverage that

Europe specific scale.

That put the company

in a tough position.

Major automakers generally want to

build flexible platforms and

parts that can be used in

a variety of models in different

markets.

This helps them keep costs low

and achieve those highly desired

economies of scale.

There are forces however that make

it difficult to share parts and

platforms.

Automobiles tend to be highly regulated

products and many of the

markets where they are sold

and the regulations can vary

sometimes widely from

region to region.

One example of this is

fuel economy and emissions regulations.

Both the U.S.

and Europe have them.

But they tend to differ and

producing cars to meet each

regulatory regime costs

more money.

It requires that the company engineer

and test every vehicle to

fit every set of rules.

But many industry observers say GM

made a number of missteps over

the years that contributed to

the brand's struggles in Europe.

Opel and Vauxhall are often thought

of as sensible cars but they

do not have the glamorous

reputations of more premium brands.

GM typically sold Opels and Vauxhalls

in high volumes usually to

keep costs low.

But simple supply and demand shows this

has a way of driving down

prices.

And while GM produced a lot of cars

it was hard for it to make

money on the cars it made.

It also introduced its Chevrolet brand

into Europe which had the

effect of undermining sales

of Opel and Vauxhall.

Both brands already had

difficulty distinguishing themselves in

Europe's competitive landscape and

selling highly similar

Chevrolets right next to

them further confused buyers.

Furthermore the company didn't

have the right products.

Opels portfolio was heavily

weighted toward traditional passenger

cars such as

subcompact and sedans.

And the brand missed the boom

in crossover and small SUV sales.

At the end of the day Europe is

a large market but it is a mature

one and does not offer the

opportunities for growth companies can

find in China and other emerging

markets or even the kinds of

opportunity in the U.S..

A lot of it is really reflection

of the economic growth in Europe

relative to China.

You have one of the fastest growing

countries in the world and the

U.S. which is growing stronger a

lot stronger than Europe now.

You know if you look at European

GDP over the last several years

just has really lagged the

North American market in Asia.

China is now the world's largest

car market with 28 million new

vehicles sold in 2018.

That number is likely to continue

to rise as the auto market

continues to grow.

In North America particularly the

United States, is becoming an

ever more profitable market as

consumers turn toward higher

priced crossovers, SUVs,

and pickup trucks.

So GM cut the cord in Europe and

said it would use the money to

focus more on its strong business

selling trucks in North America

while sinking piles of cash

into its investments in electric

vehicles and self-driving cars.

Those aren't cheap aspirations and it may

be a long time before GM

or anyone else makes

money off them.

Meanwhile GM's North American sales

have grown pretty consistently

from 56 billion dollars in 2009

to 113 billion dollars in 2018

according to FactSet.

Meanwhile it was able to sell the

business to Peugeot and a large

automaker that has been successful

focusing on Europe but who

also has plans to

return to the U.S..

They've been very open over the

last few months about their

interest in specifically

Fiat Chrysler.

Which I think they view as a

opportunity to gain a foothold in the

North American market and obviously

you know that company has

said some very well-received brands with

Jeep and a lot of the

new products that

they're introducing.

In a comment to

CNBC, General Motors

said:

Peugeot surprised the industry by saying

it had restored the Opel

and Vauxhall brands to profitability in

part by cutting costs and

introducing new more

profitable models.

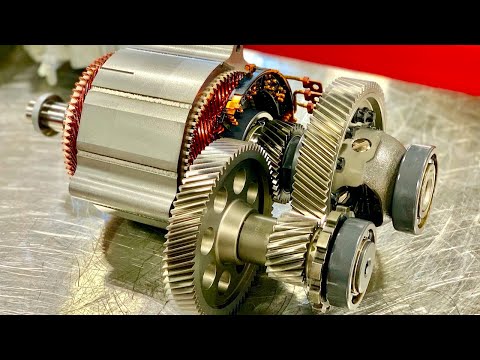

Chevrolet Bolt EV Traction Motor - Deep Dive

WeberAuto:

Hello, I'm professor John Kelly and this

is the Weber Auto YouTube channel.

In this episode we will be disassembling

the drive unit the electric motor and

gear reducer out of our 2017 Chevrolet

bolt on the hoist behind me here. now

this drive unit and electric motor

combination is is all one piece,

unlike the Nissan Leaf that has a drive

unit that unbolts from the electric

motor. This drive unit is rated at 150

kilowatts which is 201 horsepower, it is

also rated at 360 Newton meters of

torque which is roughly 266 foot-pounds

of torque.

Now let's let's talk about torque just a

little bit. That torque rating is what

the motor itself is capable of producing,

that is not the same as the torque that

ends up at the wheels of the vehicle, so

for example the Chevrolet Spark EV

produced by Chevrolet before the Bolt

here

actually had an electric motor that

produced 540 Newton meters of torque, the Bolt EV electric motor only produces

360 Newton meters of torque and so you

might be misled into thinking that the

Spark EV had more torque; well, the motor

did, but not the torque delivered to the

axles that drive the wheels. So the gear

reducer right here on the side of this

drive unit has an impact on that because

gear reduction is also torque

multiplication minus frictional losses, so

the Spark EV had a 540 Newton meter

electric motor but it only had a three

point one five to one gear reduction

unit which resulted in about 1700 Newton

meters of torque at the wheels, at the

axles. the Bolt EV electric motor

produces 360 Newton meters of torque a

whole 180 Newton meters less of torque

from the motor, but it has a seven point

zero five one eight to one gear

reduction through this gear reducer

which multiplies that 360 Newton meters

of torque by seven point zero five one

eight, which gives us over 2,500 Newton

meters of torque at the axles. So there

are other electric vehicles out there

that are being produced right now that

have higher torque higher motor torque

than the Bolt EV

but what would be interesting, I and

I don't know what their gear ratios are

yet, is to see what is the torque

actually to the axles what's the torque

to the ground because that's what you'll

feel when you step on that accelerator

pedal, that's the torque to the wheels

that makes the vehicle move. The design

of this drive unit this electric motor

it has a peak amperage draw of 400 amps

versus 450 as for the Spark EV so it

uses less current to provide more torque

so it's a more efficient better design

electric motor. The electric motor in

this drive unit spins clear up to 8810 rpm where the

Spark EV only spun up to about 4500 rpm,

and we'll take a look at some

differences in the electric motor design

and the stator winding design that

allowed it to spin at those higher rpms

without the AC losses that typically

occur at higher rpm. As mentioned in the

previous video on high voltage

components of the Chevrolet Bolt EV this

drive unit uses about 2.9 litres, around

3.1 quarts of Dexron HP fully synthetic

base transmission fluid automatic

transmission fluid. It also is cooled by

the General Motors Dexcool 50/50 mix

of coolant and deionized water. Okay

let's take a look at the outside of the

housing here of this drive unit. The

official name or designation of this

drive unit by General Motors is the

1ET25. The one means it's a one speed

trans axle, this doesn't shift, E means

it's electronically controlled, T means

it's a transaxle, and the 25 is a

relative torque rating. Alright, right

here on the front of the transmission is

the actual last eight digits of the

vehicle identification number and you

can see that MMF right there, that is

the three-digit regular production

option code the RPO code that you can

find on label in the back of the Bolt EV if

you take out the lower compartment

carpet and look in what looks like a

spare tire tub, there's a label on the

driver's side that has a whole bunch of

three digit codes on it

MMF just means that's which transaxle

or transmission this vehicle came with.

Okay right here on the top of the trans

axle is the transmission range selector

actuator and this is a brushless DC

motor with a gear reducer that actually

moves the shift lever to put us in to

Park reverse neutral Drive and low, now

technically inside of this drive unit it

there's really only park and not park,

but there is a position sensor in here

called an internal mode switch that will

monitor which position the transaxle

range selector is in so that the vehicle

can act appropriately. For example the

shifter itself on the center console is

not directly connected to the drive unit,

it's just an input to the computer that

controls this actuator, so when we go to

the reverse position for the neutral or

drive or low, there's a feedback on the

internal mode switch electrical

connector right here, that lets the

engine control module, even though this

doesn't have an engine, know which gear

range you have selected so that it can

request the trends axle act

appropriately. Also, right here by the

electrical connector for the internal

mode switch is the transmission fill

plug, so if you want to put fluid into

this transmission you need a 14

millimeter wrench or socket to take this

plug out and put the Dexron HP fluid

into the transmission. There are two

drain plugs on this transmission, one for

each side, so there's one down below on

each end of the transaxle the driver's

side and the passenger side, there's

there are two separate drain plugs to

get the fluid out of each side, now

there's only one fluid that goes

throughout this entire transaxle but

because of how its baffled and set up

inside to remove all the fluid you need

to remove both plugs.

Now speaking of fluid and fluid level

when you drain fluid at whatever the

recommended fluid change interval is or

if you're doing service work on the

transaxle here and you're adding fluid

you need to know when to stop adding

fluid, so on the other side of the

transaxle right here is the transaxle

fluid level check plug, so the drain

plugs right down here, the fluid level

check plugs here, the fill plug is on the

other side so you take the fill plug out

you take the fluid level check plug out,

and you add fluid until fluid comes out

over here, and then you let it sit and

stabilize for a minute add a little bit

more and make sure that fluid comes out

comes out to a slow drip, and then the

instructions tell us to put both plugs

back in and go drive the vehicle until

the transmission fluid temperature

reaches 35 degrees Celsius or 95 degrees

Fahrenheit and then double-check the

fluid level again to make sure that

comes out at a very slow drip. Alright,

while we are here on this side of the

transaxle we have an electric motor an

electric pump for the transmission fluid

so there's a big filter we'll see when

we take this thing apart down the bottom

center of this transaxle it will pull

fluid up from the filter and then put it

into what's called the oil sump so the

oil sump is basically just a great big

bathtub looking area up here that the

pump fills full of fluid and then there

are these little drain channels that

fluid drains down to cool the stator

windings and lubricate bearings and so

on and we'll see that once we get the

cover off so we have an electric 12 to 14

volt driven electric motor that pumps

fluid throughout this transaxle. From

what I read this pump only works when

you are in Reverse or Drive, it does not

pump when you're in park or neutral.

Alright, we have another electrical

connector right here, this connector is

for the resolver which measures the

angle of rotation the direction of

rotation and the speed of the electric

motor rotor itself, and then there's a

transmission fluid temperature sensor

that is in the bottom of this

transmission case cover here. All of

those are accessed electrically through

this electrical connector right here. As

you may have seen in my other video on

high-voltage components we have the air

conditioning compressor of the bolts up

here and then we have our coolant pipes

that go into what's called a coolant

sump in the bottom of this transaxle and

we'll see that here in a few minutes but

we have coolant going in coolant coming

back out and goes through a series of

cooling fins and cooling circuits to

absorb heat from the transmission fluid

right here on the back we have the

electrical connection for the

three-phase cables that come from the

the

single power inverter module that sits

two modules above here. Three-phase

orange cables come down to drive the

electric motor, there's a cover

the cables bolt on and then there's a

cover they'll holds the cable in place.

We have a transmission vent right here,

let's just take that vent off while we

vent tube off while we're here now you

can see the oil sump area again on the

top and the cooling sump coolant sump

area here in the bottom all right there

is one additional plug on the side of

the case with the electric motor and

there's nothing in the service

information to indicate this but I

believe this is a pressure test plug to

check the pump output pressure, but I

can't find any information on what that

fluid pressure should be. Okay, I'm going

to be disassembling this transaxle right

here on the workbench but there actually

is a special fixture to hold this

transaxle and allow you to rotate it and

disassemble different pieces of it and

still be able to rotate it for

convenience. I have this special adapter

as you can see here in this photograph

but the way it's mounted it's too high

and too difficult for me to disassemble

in that holding fixture being in a

wheelchair, so the workbench is where I'm

going to disassemble it, but I wanted you

to know there is a special fixture for

that and I tried it it just doesn't work

for me.

by the way this transaxle weighs about a

hundred and seventy pounds or 77.4

kilograms. Okay, well we're ready to

start disassembly, the first step is to

remove this oil pump the 12-volt power

oil pump, it has three bolts right here

and a few seals underneath it as you can

see here there are two seals that seal

the pump to the transmission case right

here there are two bolts that hold the

cover over the pump gears themselves

there are no instructions on

disassembling this so I assume we're not

supposed to disassemble it but that's

exactly what I like to do

take things apart I'm not supposed to as

long as I can get them back together and

make it work again here we go we've got

a Jew rotor style oil pump there's an

o-ring right here that needs to fit in

this groove to seal and then the cover

just bolts on okay the next thing on the

list is to remove the left-hand and

right-hand output shafts that go into

our differential side gears in the gear

reducer this is the left-hand side right

hand side over there it calls for a

slide hammer and a old pilot bearing

removal tool for a manual transmission

so this is the pilot bearing removal

tool right here and a slide hammer and

we are supposed to put this up inside

and put it into the snap ring groove for

the CV shaft and then pop it out well

come to find out the snap ring groove is

thinner than the tip of this tool that's

supposed to go into it and I didn't

realize that's what the problem was and

I had a hard time getting these output

shafts removed I finally got him out but

once I got a mound got looking at the

tool versus what they were supposed to

be grabbing I realized I need to grind

these down make him a little thinner so

that they'll actually fit into the

grooves of the her for these CV shaft

snap rings that are there so since I've

had this entire transaxle apart before

and I'll put it all back together

I've removed those snap rings they'll

hold these output shafts in place so I

can just pull them out by hand right now

this big long left hand output shaft

goes right through the center of the

rotor of the electric motor itself it's

it's hollow in the middle

and it has a big heavy-duty bushing

right here on the outside with the axle

seal and this is our left-hand output

shaft and then the CV shaft itself plugs

into here that goes to the left front

hub and bearing assembly and tire and

we'll assembly so there's our left-hand

axle shaft there's a snap ring that fits

in that groove right there typically and

I've just removed and I've just removed

that snap ring for ease for this

demonstration here obviously I'll need

to put that back in when I reassemble

so that's the left-hand axle shaft on

the other side we use the slide hammer

again and pull out the right hand axle

shaft as you can see this one is much

shorter than the other one and it has

the support bearing in the differential

case itself that holds it in place and

its own snap ring that I've already

removed and of course an axle sill here

on the other side as well okay the next

thing on the list is to remove this

transaxle case to remove the case I've

got to take the linkage off and our

actuator off and then we've got these

bolts to go all the way around and then

we'll be able to see the gear reduction

transfer gear and the final drive ring

gear and differential gear set so I'll

take the clip out and lift up for a

linkage on the shift actuator and then

take the bolts out

okay here's the shift actuator assembly

itself transmission range selector

actuator kind of a great big piece I

I've seen some of these that are smaller

right I'm not sure why this one is so

giant I'm not I've never seen one this

big but it obviously does the job of

mechanically shifting the transmission

range lever since you have an electronic

shifter on your center console alright

let's take these bolts out of the trans

transmission case okay I've got all the

bolts out of the transmission case now

we can attempt to slide it off it has a

couple of dowel pins they'll hold it in

place there's a couple of pry points

plus one right back here and another one

right here there we go

I'm going to come in with a plastic

mallet here and just tap lightly there

we go okay we can see inside of the

transmission case itself and the only

things in here of real interest are the

transmission internal mode switch right

here we got the electrical connector

right here harness right there that

connects to this outer blue connection

connector that will read which Range

Park reverse neutral low you have

selected with your transmission shift

lever and then we have the parking

linkage right here we've got Park

reverse neutral Drive

and low now of course normally

transmission fluid would would be

pouring out of here of whatever didn't

get drained out when you drained it

previously but I've had this apart and

cleaned everything up before we have our

ring gear right here and our

differential gear set and as notice we

have real nice ball bearings here these

bearings since their ball bearings

instead of tapered roller bearings have

to have in place shims so there's a

special shimming procedure to control

the end play of these bearings that will

have to go through when we reassemble it

so you're supposed to take these shims

off and throw them away well and then

replace them with new new ones when you

go back together I suggest that you take

them off and measure them and then hang

on to them because you might you might

need them again when I took these off

previously and measured them they were

almost all identical in the thickness so

there are six of these shims for the six

ball bearings that are in this transaxle

four of these shims measured exactly

half a millimeter in in with the other

two one of a measure one millimeter in

width and the other one measured 0.9

millimeters so you need to keep track of

what thickness shim you had where and

write those down so that you you'll have

an idea of at least what it was before

you took it apart now if you're just

going back together and you haven't

changed any shims or any parts inside

just reuse the old shims but if you're

changing a bearing or any of these

internal pieces you need to go through

the special measurement procedure that

we'll see when we go back together to

determine if these shims are correct

okay so there's there's special shims on

each of these

bearings I've measured all of them RIT

written their dimensions on the ziploc

bag here that I keep them in and will

refer to those when we go back together

all right now we just need to remove the

counter gear right here and the final

drive a ring gear and differential gear

set this is where our short little

output shaft plugged in right here and

then our long one came all the way

through on the other side okay before we

remove these gears there is a an

aluminum gasket with a rubber seal

embedded into it the instructions tell

us that is not reusable

there is also an oil baffle right down

here to channel transmission fluid away

from the ring gear to reduce losses as

it rotates into it and to splash oil up

into different channels to lubricate the

the bearings if we look in this case

half right here you can almost see what

looks like a funnel right there for the

fluid to drain back down and lubricate

this outer bearing and a similar one

here on this other other side for that

bearing so we've got a oil baffle to

remove all right I've got the oil baffle

removed on the other side of that is our

magnet for metallic particles from gear

normal gear wear and other malfunctions

okay now we're ready ready to remove

these gears pull out on the counter gear

and then pull out on the final drive and

it'll come right out if you don't pull

out on that counter gear first there's

not enough clearance for the final drive

Unit two clear so here's our final drive

you can see our open differential gear

set inside there here's our sim on the

other side as well

all right the instructions tell us that

we can if we won't want to remove the

park linkage in the internal notes which

I don't really care about that that's

just regular stuff that you'd see in any

other automatic transmission so let's

continue on with things that are unique

to the bolt

evie drive unit here the one ET 25

transaxle so let's turn the transmission

case around and we'll take off the

transmission case cover here on the

driver's side

now the SAE document the details the the

bolt evey drive unit here that I told

you about in the high voltage component

video tells us that the drive unit

itself was designed to be serviceable in

the vehicle that's why they have a case

removable case cover on one side and a

case cover on the other side for the

gear reduction unit you can leave this

Center portion with the electric motor

in it in the vehicle and just remove one

or both case covers to do service work

on components inside the case covers

seal replacements resolver replacements

internal modes with replacement and so

on but anyway we're going to take off

this case

cover next from the driver's side all

right this case cover is going to be a

little harder to get off than the other

one because the rotor that has internal

magnets embedded inside of it has now

magnetically pulled itself over to the

stator because we are no longer

centering it inside of the stator itself

and so it puts a it pulls it off to the

side just a little bit so there's a

prying

right here

and there's a pride point right down

here another prior point right here

there we go okay so here's our case

cover and it has an aluminum gasket

that's not reusable as well our case

cover has this long transmission filter

that's not serviceable without

disassembling things as you can see has

a temperature sensor down inside of it

right there and then this is our

resolver our serviceable resolver that

measures the position speed and

direction of rotation of the electric

motor rotor inside the transaxle here

let's turn this around oh by the way

down inside of the bearing housing there

is a shim for the ball bearing right

here on the rotor itself so we're

looking at the stator and the hairpin

six conductor deep stator design a

unique design we'll talk about that a

little bit more once we get the stator

out we have a lubrication channel right

here where fluid is going to drip out of

our oil sump and run along and drop down

on to the stator windings themselves and

cool the the stator windings it also has

a drip channel that comes over and goes

down to this bearing here to lubricate

it

so we've just got an 8 millimeter head

bolt holding the filter in place and as

you can see the filter just has an

o-ring seal on the one side and you can

see the pick up filter screen filter

element on the inside so this is going

to reach all the way in up underneath

the the stator itself to pick up the

fluid on the back side of it and on the

back side of it is the inlet of the

coolant so that would be the cooler oil

on the back side there all right then on

the resolver it just has eight three

eight millimeter head bolts to hold it

in place and one electrical connector

this resolver only bolts in in one

location it's not adjustable it has

automatic learn unlike the older Toyota

Prius resolvers that that would actually

come out of alignment

if you unbolted them and there was no

way for you to line them back up okay so

here is our resolver pull back on the

connector position assurance clip

depress the tab and remove the resolver

itself the resolver is a serviceable

unit when and if it ever goes bad but it

should should never go bad all right

then the remaining wire harness and the

pass-through connector here just goes

over to our temperature sensor okay next

on the list we need to remove what is

called the center support this is what's

supported the driver's side ball bearing

of our differential case assembly

okay this is our center support it's

held in place with six bolts and aligned

with two dowel pins right there now with

that removed there's nothing to stop our

transfer gear from sliding out it's just

a tight fit on the bearing in the bore

as it should be just pray lightly

sometimes these will just slide right

out and right in and other times they'll

they'll fight you here we go okay so

here's our transfer gear it's ball

bearing and shim so put that shit over

here with the others okay right here in

the end of the case we still have a

lubrication channel right here from the

oil trough the oil sump I mean right

there and then we have a cover for the

three-phase electrical connector right

here as well then on the other side we

have that oil distribution channel right

here that cools the stator so we've got

to remove that we are now to the point

where we are ready to pull this rotor

out but we just can't grab on to it and

pull it out it has some super strong

neodymium magnets multiple layers envy

configuration inside of this stator

you're not going to pull it out by hand

and you sure don't want to come in here

and start prying on it so the only way

to get that rotor out of there if you

want to remove it for service replace a

bit bearing on it or the gear on the

other side or another bearing or just

replace the rotor itself for whatever

reason loss of magnetism and trouble

code sets or whatever

it takes a special tool to pull it out

without having it rub on the stator

frame itself and without having it

injure you with you trying to pull it

out and it's pulling back in with all

its magnetic strength so true get that

out there's a special guide tool that

will hold it centered in the stator and

we need to set that up next and it

starts on the other side here so there's

a special tool kit that costs almost a

thousand dollars to Center this rotor as

you pull it out I found one on eBay for

a little bit less than that but but it's

a very expensive tool but if you want to

do service work on this transaxle you've

got to have it so let's bring in the

special tools okay so I brought in the

special tools to keep the rotor centered

there's a special spacer with a notch in

it to clear that notch right there this

is just gonna fit in there just like

that then there's a plate that bolts on

over the top of this to hold it in place

these don't need to be super tight

they're just holding that little spacer

in place so I'll just lightly Snug those

up then there's a sleeve here that's

supposed to fit down the center of that

rotor but these sleeves are a little bit

too big I've had to take sandpaper and

send them down to make them fit inside

of this rotor and I don't know if that's

because the tools were made for a first

design rotor and then they changed it or

if they just made the tools incorrectly

but these tools are from what used to be

can't more tools the special tools

supplier for General Motors it's now

Bosch service solutions so Bosch you may

want to take a look at this this tool

here the DT five two zero one one

- one - three because it doesn't fit

it's not doesn't Center up inside the

the rotor as well as it should

i've had to sand it down just a little

bit and then i'm able to tap it in a

little bit there but I think that it's

supposed to be if it's supposed to be a

tight fit but it should be able to slide

in by hand I believe then we have a

guide pin that's going to go through the

center of that then we have this outer

housing the bolts in place to hold the

guide pin in place so the blue sleeve

this one here because there's one for

the other side also centers the rotor

into this plate and then this sleeve is

centered into this plate so we've now

centered the rotor on this side of the

stator so now we need to go to the other

side to put additional tools in to get

it centered and then pull it up and out

okay at this point if I had the

transaxle mounted in that special

rotating holding fixture I would just

simply rotate it on its side and get the

get the rest of the tools hooked up but

I don't I'm not able to use that so I'm

just going to put some extra long bolts

in this side of the case to hold the

case up off of this tool when I tip it

over to support it as we pull the rotor

out

okay so here we go we're going to tip

the tip the whole thing up on its hand

just like that so now we've got

clearance for the tool underneath and we

can get the upper tools set up to pull

the rotor up and out all right while

we've got the transaxle tipped on its

side let's take this oil sump cover off

and show you what's inside of there so

it's just a big empty trough and you can

see has one two three four five six

holes in it where fluid is going to go

out and drip down on other parts inside

of the transaxle for stator cooling and

for the ball bearing lubrication the

cover itself has that same aluminum

gasket that's not reusable also while we

have this transaxle on its end let's

turn it over and take the coolant sump

off next okay here's our coolant sump

you can see this pipe right here is

where the coolant comes in and it has to

wind back and forth back and forth and

then come back out over here the coolant

sump which is visible from the bottom of

the car with the under car cover removed

also has that same aluminum gasket

that's not not reusable why are they not

reusable I don't know maybe the aluminum

crushes these I'm going to see if I can

buy replacement gaskets at the local

Chevrolet dealer it seems like I saw a

service bulletin saying that all these

parts are serviceable now and it gave

the part numbers for them but if not

none of these are damaged it only has 35

miles on it and I'll reuse them and see

what happens

okay so coolant sump oil sump so now we

are ready to pull out the rotor assembly

so to pull out the rotor assembly we

have a guide pin it's going to come in

and screw into that dowel they had a

threaded end on it all right so this

threaded guide pin did not line up

exactly perfect with the guide pin down

below I can't tell if we're just

spinning the whole thing there we go

all right it's screwed all the way into

that alignment dowel from below now we

have this tool that has three holes that

go over the holes where the stator bolts

are so we need to remove the stator

bolts next these stator bolts are not

reusable three stator bolts so we put

this tool over the top of that we want

to be very careful that we don't damage

pry lean or set anything on the stator

windings here that could cause damage to

them so we'll get that lined up just

like that now I'm going to reposition

the camera so you can see

how tall this next tool is that fits on

here all right we have two clamshell

type tools that are going to come in and

clamp down over the resolver cam rotor

there and this bearing they're gonna go

just like that except I need to split

them apart so I can get the next tool in

it says this big tall piece right here

that's going to go over and down into

our stator bolt holes so we've got this

threaded shaft we've got this adapter

right here that these little clamshell

tools are going to hook into and then

the threaded shaft with a nut on the top

of it we're going to tighten that nut

and pull the rotor up out okay so the

tricky part of giving this hooked up is

getting both of these

clamshell tools over this lip right here

so I have to loosen the nut on the top

and let it come down let me turn this

you can see what's going on

there we go okay so we slide that open

clamp the clamshells around it put this

sleeve over the top of it to lock the

clamshell in place snug up this nut to

hold the lock in place and then from the

top here we start to pull up on the

rotor itself I'm going to get

repositioned bring my chair up a little

higher here so I can reach that nut it

takes quite a bit of turning to pull

that out okay here we go thirty

millimeter wrench we want to turn the

nut and prevent the shaft from turning

so I'm just going to hang on down here

as it comes up those guide pins the

guide dowels keep it from rubbing on the

stator frame although although there's

almost a strange ratcheting sound as I'm

pulling this out that makes me think

it's barely contacting the the stator

laminations or the rotor laminations

anyway we'll pull it out and take a look

see if we can see any witness marks you

can see the top of the rotor now is

starting to appear

I think we're finally clearing the top

of the yes we are it all of a sudden got

real easy to turn the nut so we no

longer have the magnet pulling out or

resisting us pulling out okay you can

see the entire length of the rotor here

get another bearing down below it and a

gear below that now we're supposed to

just lift up on this and and pull it out

I'm not sure if I'm strong enough I may

have to bring in the the engine hoist to

pull it out of here but it's just

sitting on these three non-magnetic

aluminum poles here and we've got the

weight of the the rotor assembly itself

I measured it earlier but I can't

remember what it is at this moment but

let's see if we can lift this up and out

though I cannot so let me get the engine

hoist we have to lift it up high enough

to clear that alignment dowel so I've

got to lift it up probably four more

inches 100 millimeters or so okay I've

never tried this before it's just a lift

strap let's bring it up

okay the lifting or the tool was getting

stuck in one of the holes for the the

stator bolts there we go

okay here we go

and we've cleared the alignment dowel so

slide the case out of the way here and

we'll let that back down

oh let's see how much that weighs it

says it weighs 60 pounds with the tool

the tools probably 10 pounds of that

okay we have to remember that this rotor

is highly magnetic very strong eight

pole magnetic field around this thing

and so we need to keep it away from

anything any metal particles or any

tools or anything else that could cost

cause it to receive damage on its

laminations here in looking at the the

laminations from removing it I don't see

any obvious damage at all there let's

let this down and take the the tool off

and just look at the rotor itself

little clamshell pieces out of there

these tools are magnet earth iron some

some sorts so we got to keep those away

from the magnetic field as you can see

these blue bars are aluminum they're not

sticking to the the rotor itself and

then plastic of course works great with

the magnetic fields so now we've just

got our rotor we've got our drive gear

down here I've got a ball bearing and

another ball bearing there's another

shim down inside the case a bigger

diameter shim for this bigger diameter

bearing all right I'm going to get some

wooden blocks to put this in all right

here's the rotor for the bolt

evie as you can see this bearing seems

to have some sort of a gray coating on

the outer race where this one does not

and on the counter gear bearings they

also have this gray coating it doesn't

say anything about what that gray

coating is for I suspect it's to prevent

corrosion from the dissimilar metals

with possible induced currents going

through them with the the motor running

vehicle going down the road I've seen

this type of coating on universal joints

in universal joint caps universal joint

caps bearing caps in an aluminum

driveshaft the same color I don't know

if it's the same material but if any of

you know what this coating is for if

you'd please put that in the comments

below I'd appreciate that

I'm just speculating okay so we've got

the rotor out of the way this is a

serviceable piece now the last piece to

remove is the stator assembly itself and

it has three special guide pins that go

into the stator bolt holes and screw

into the transaxle case and then they're

tapered on the top here and that's to

allow you to slide the stator out

without it binding inside so I'll slide

that over there rotate it down and just

pull out slightly

here it comes just like that so here's

the stator for the Chevrolet bolt Eevee

if we zoom in close and look at the

stator windings you can actually see

there are 1 2 3 rows of these hairpin

conductors which means they are 6

conductors deep in this stator and from

what I read in the SAE document on this

new improved motor that helps reduce the

AC power losses at the higher motor rpm

a typical stator like in the previous

Chevrolet Volt had 2 rows instead of 3

so they were four conductors deep in the

Chevrolet Volts and six conductors deep

here and one of the people that was on

the original design team for the

Chevrolet Volt told me that when they

designed this electric motor and it's

designed for maximum efficiency and hand

power that there was no other motor out

there that could even match the

efficiency of this motor and they said

that they designed this motor to be the

next small-block Chevrolet so to say of

power trains so the small-block

Chevrolet was and still is a very

popular very powerful v8 engine and has

been for many many years and their

intent was to have this motor design

maybe even this drive unit be in

multiple platforms with the same high

power high efficiency motor system if we

look at the other side here of the

stator windings you can see the the

other end of the hairpin conductors and

then there's a drip channel right here

for oil to come out of that oil sump and

to drip down and go down and lubricate

the stator windings because these get

really hot this is the heat source

inside of the transmission and it and

although it gets hot it doesn't get as

hot as the fluid

although the fluid gets hot it doesn't

get hot as a normal planetary gearset

style automatic transmission and the

cooling system surge tank reservoir cap

was only pressurized to 5 psi for this

loop of the cooling system so much lower

amounts of heat compared to an internal

combustion engine with a torque

converter heat generating planetary

gearset style of automatic transmission

now just a couple of things to get

wrapped up with this disassembly video

because we will reassemble it showing

the special measurements for the shims

and everything when we go back together

but one thing I wanted to show you about

these electric vehicles is how simple

they are and when I mean when I say

simple I don't mean simple design

meaning it was easy to design these

simplicity is not necessarily easy but

if we look at the number of rotating

parts in this entire drive unit

there are basically three main rotating

parts we've got the rotor assembly that

then turns the counter gear right here

that then turns the final drive three

pieces no clutch packs no bands and no

sprags no roller clutches no Pistons

none of those hundreds of parts that you

would see in a typical automatic

transmission let alone the internal

combustion engine that this is replacing

of course there are three main moving

parts these pieces here but each one has

two bearings on it so there's six more

pieces so there's nine total and then

inside of the differential here we have

two side gears and two differential

pinion gears so that makes for a total

of 13 possible moving parts inside the

of this drive unit and only when you're

turning corners would the side gears in

the differentials

be rotating at a different speed than

the differential case so a real basic

very reliable system these electric

vehicles and and this one is is very

efficient and that the design is very

compact to where this left-hand output

shaft remember goes right through the

center of the rotor instead of being

offset like on the the Nissan Leaf and

other electric vehicles out there so

congratulations to Chevrolet and the

design team that came up with this

amazing and efficient and simplistic

evie drive unit and I think it's

absolutely beautiful so coming up I hope

to shoot a reassembly video with all the

measurements for this drive unit and

then we've got all of these parts out

the drive unit all of the electronics

and our and our Chevy bolt back here on

the hoist is totally empty yeah under

the under the hood so we've got to put

that all back together and and make it

work again even the battery is out the

whole thing is stripped as far as the

powertrain is concerned and we're gonna

put that back together and and make it

work and hopefully get it converted to a

DC fast charge thank you for watching

Why Ford and GM Scaled Back in Europe | WSJ

Wall Street Journal:

(thoughtful music)

- [Narrator] Take a look at this map.

It shows 23 plants that Ford

has in Europe from the UK to Russia,

but recently, Ford laid out plans

to cut six of these European factories.

- So six of 'em, they're gonna sell one.

They're closing several,

they're gonna lay off about 20%

of their workforce there,

which is about 12,000 people.

- [Narrator] But Ford is

not the only U.S. automaker

that's scaling back in

Europe, two years ago

General Motors pulled out of

the market almost entirely,

selling their European brands

to French car maker Peugeot.

Both companies expanded

to Europe decades ago

as a wider strategy to scale globally,

but they both had trouble

making money in the region.