Troubleshooting a No Start, No Spark, No Fuel, No Com (any car)

ScannerDanner:

Throttle Body Coolant By-Pass line Modification/Performance Upgrade - For Tropical Climate Part 4/5

sTeVeXNYCPerformance:

Desmontar Tablero Chevrolet Aveo / JMK

JMK Automotriz:

Hello people from the new generation!

today we will show you how to dismantle a Chevrolet Aveo dashboard

...it is going to be something really easy

you just need as always to be very careful to not to break any of the pieces

let´s take a philips head screwdriver

we are going to find two cross screws in this part above

they are the first we need to remove

you are going to remove them and now pull from this side of the board towards you

pop it out in this way

in this coming step be careful; you are going to insert

your fingers as much as you can in this edge from behind

in order to pop out some clips

if you just pull them straight, you might break them

so be careful... you are going to do it the way I´m doing it

in that way; by pulling it from behind

so you won´t break it

here we have two more screws

once you removed the screws, you are going to pull the board towards you

ups...I was forgetting that there are two more screws in here!

they are a bit hidden

you are going to find them in this part above...sorry I was forgetting them

these two drivers...

now we have removed them, pull your board

and unplug the harnesses it has behind

and now it is dismantled

well today we had a slight mistake but we aren´t perfect ...

but even like that we dind´t damage any of the parts; they don´t have any scratch

that´s the way you should work!

Well that´s it; I hope we have helped you

any suggestion, you may leave it in the comments below

SEE YOU IN THE NEXT VIDEO!

Decoding a CAN bus signal

PicoScope Automotive:

Hi good morning

We are about to show how to use the CAN breakout

box from our previous video

To look at a CAN bus signal and decode it

I will explain how to get to the menu we have

here

What you need to do is go to tools

Serial decoding

And create

Then channel data

Channel A

Tick the

invert box

Select high or low CAN

Channel name

Between rulers

Then OK

And then we have done exactly the same for

channel B

High CAN

Channel name

Tick the box

Inverted

And OK

When you normally start on this menu first

of all

You have a list of all the systems you can

pick through

But we have done that previously

We will start the car up and show you our

bytes of information

And see what we can see on the bottom of the

car

We have packets of data here

As you can see on the screen we can zoom in

on any particular part

And look at what we have

You can see the packets of data either on

screen or into this Excel file

And see what we are getting

Many vehicle manufactures are not going to

tell you what the data means

But we can look to see what is happening and

what is going on

And get the information

Sometimes some technicians find it easier

to look at the signals

Through the data here rather than on the screen

So just a small video to show you where to

go

Just remember you need to go to the Tools

button

Then Serial Decoding

And follow the menus through while watching

this video

Thank you

Inspección de Sistema CAN

Diagnostic Scan Tool G-scan3:

En este video, vamos a hablar sobre la comunicacion

de protocolo en el estandar de OBDII, el cual

es controlado por el Sistema CAN Automotriz.

Además vamos a hechar un vistaso a algunas

caracteristicas geniales de nuestro G-Scan2

con más videos.

Hace tiempo atras cuando el mundo no tenia

conciencia sobre los cuidados del ambiente,

se usaban pocos sensores y modulos en los

autos.

En esos tiempos, todos los sensores y modulos

eran conectados des de un punto a otro en

cables porque no era necesario conectarlos

entre todos para intercambiar informacion

en tiempo real.

Con el paso del tiempo las regulaciones para

la proteccion del ambiente se han ido poniendo

cada vez mas estricto siendo necesario la

incorporacion de mas y mas sensores y modulos

en los autos para el control de la emision

de humo en el tubo de escape.

Se vieron la necesidad de compartir informacion

en tiempo real para la eficiencia del control

de emision de humo.

Esto quiere decir que el auto vendra equipado

con mas cables para estar conectados entre

si, causando mas peso en el auto, un sistema

mas complejo y eventualmente un alto costo.

Para optimizar la eficiencia de las conexiones

de red, el sistema CAN automotriz fue desarrollado

por Robert Bosch en 1985.

El sistema CAN permitio la comunicacion entre

los diferentes modulos entre si utilizando

un cable comun.

En 1993 la Organizacion Internacional de Normalización(ISO)

lanzó la norma CAN ISO 11898.

Luego en ISO añadieron varias versiones como

ISO 11898-2 (CAN de alta velocidad), ISO 11898-3(CAN

de baja velocidad tolerante a fallos).

Existen muchos tipos de CAN bus, pero para

mantener la simplicidad de este video no entraremos

a fondo de cada tipo.

Ahora, vamos a enfocarnos en ver las diferencias

mayores entre los tipos mas usados.

CAN de Alta velocidad y Baja velocidad Tolerante

a fallos.

En la industria automotriz, ISO 11898-2 (CAN

de alta velocidad) ha sido el protocolo mas

usado debido a su rapido ratio de transferencia

y simplicidad del cableado entre los modulos.

El CAN de alta velocidad permite la transferencia

de hasta mas de 1Mbit/seg y utiliza bus lineal

con resistencia de terminacion de 120ohms

ubicado en cada extremo.

En lugar de tener dos resistencia de terminacion

en cada extremo, el ISO 11898-3(CAN de baja

velocidad tolerante a fallos), tiene la resistencia

de terminacion ubicado en cada modulo y la

resistencia supera los 100ohms.

Dado a la terminacion individual en los modulos,

el CAN de baja velocidad tolerante a fallos

permite al CAN bus la comunicacion en caso

de haber fallas en el cableado.

Esto permite un rango de transmision de entre

40Kbit/seg a 125Kbits/seg de velocidad de

baudios.

Cuando surge un problema en la linea de CAN,

Los sintomas pueden ser variados empezando

desde error de comunicacion entre modulos

hasta una conexcion completamente imposible

con el scanner.

Usted puede diagnosticar autos manualmente

usando el juego de osciloscopio pero probar

con las agujas en los puertos correctos de

OBD y analizar las graficas continuamente

puede ser incomodo muchas veces.

¿Pero que tal si su Scanner pudiera verificar

la linea de CAN con solo conectar el cable

DLC?

El G-scan2 ofrece funciones comodos y simples

para realizar una verificacion premilinar

para la linea de señal del CAN atravez del

conector DLC.

En el menu de utilidades, seleccione inspeccion

de comunicacion lineal.

Tendra opciones para elegir los protocolos.

En este video les voy a mostrar el sistema

de CAN de alta velocidad.

Necesitara poner las llaves de auto en posicion

ON y conectar los cables DLC y darle al boton

OK.

En el lado izquierdo de la pantalla vera numeros

de pin altos y bajos.

Usted puede cambiar la localizacion del pin

en configuraciones.

La configuracion predeterminada para la linea

alta es 6 y la baja 14.

Si la Linea CAN esta funcionando apropiadamente

en orden, el indicador parpadeara.

Esto es para una revision rapida para ver

si hay signos del sistema CAN pero recuerde

que esto no representa la exactitud de las

señales.

¿Que tal si quiero verificar las señales

de ondas de CAN?

Para complementar el diagnostico, usted puede

ver las formas de las ondas en vivo de las

señales altas y bajas del sistema CAN seleccionando

estas ondas en las partes superiores y inferiores

en la pantalla.

Aqui arriba representa una señal alta de

CAN y abajo representa una señal baja.

Esto señala el voltaje del cursor A y B,

y el promedio de voltajes de la onda entera.

Por ultimo, G-Scan2 ofrece una simple verificacion

de valor de resistencia terminal.

Sin probar manualmente su multimetro al puerto

de OBD, usted puede verificar la resistencia

terminal del CAN bus con solo conectar el

cable DLC.

Esta verificacion premilinar tan simple puede

ayudarle a ahorrar su tiempo.

Engine Control Module (ECU) Ground Circuit

ADPTraining:

COMO IDENTIFICAR SI ES FALLA ELÉCTRICA O MECÁNICA! (MISFIRE)

Autodiagnostico Detroit:

how to install an alarm car security system

connectedcaraudio:

welcome to the how to install a car

security system tutorial

in this video we will go over the

necessary steps it takes to install

security system

and its components the tools you will

need to install security system include

a multi-meter various test leads

a soldering iron electrical tape

socket set power drill

pick tools a crimping tool

wire strippers wire separators

any light the parts you will need to

install a security system include

rosin core male connectors

T taps and depending on your vehicle

relays diodes and resistors there are

seven main steps

to installing any alarm these include

downloading tech notes

prepping the harness disassembling

panels

installing security extras mounting the

alarm

locate tests and integrate and finally

testing the unit different makes and

models of vehicles

had different wiring schematics so when

order to determine what circuit

interface into

you must know where the circuit is

located in the vehicle

the text sheet tells you were each wires

located

the color of the wire and is polarity

you can find texts from vehicle forms

once you have found the text sheet

make sure to print it out and bring it

with you to the alarm prep area

upon first glance at the harness the

sheer amount all wires can be

intimidating

to even the most experienced dollars but

luckily

we will have to use but half of these

wires, these alarms are designed to fit

every vehicle on the market

so they give you all the wires necessary

to integrate into all them

so let's prep the alarm for type vehicle

you're working on

grab you take sheet and install manual

with the security system

and bring it to the test bench first on

the list

you will see a 12 volt constant, switched ignition

starter interupt and ground wire, these

wires

on your lower are always connected do

not cut them off

if you have electric door locks use

these wires to unlock

and lock your doors via remote if you or

your customer

does not have electric door locks save

this harness

in the box just in case you or your

customer

want to upgrade to electric door locks

in the future by adding actuators

the wires in the door lock harness can

look very similar in color

to the alarm main output harness especially

when the harnesses are all taped up

to distinguish the wires from each other

take a drill

insert the wires and twist them, so later

you know

that the twisted wires are the door locks,

your vehicle

will either have positive door triggers

or negative door triggers

if you take notes a you had negative

door triggers

then you will not need the positive door

pin input cut it off

if you text she says you have

a positive door trigger

then cut off the negative door trigger input

wire

you will not need it look at your tech sheet

does show that your vehicle is equipped

with a hood or trunk pin

some vehicles do not have these pins installed from the factory

if they do or if you plan on adding a

pin switch later

keep this wire if not cut the wire off

in a alarm you can use a horn to sound

the alarm

instead of a siren if you plan on using

the horn

keep this wire if not cut it off

usually the horn is connected to save

money on the cost of a siren

if your vehicle does not have an electric trunk pop

or you do not plan on adding one later

cut this wire off

if you are using a siren to sound the

alarm keep this wire

if not cut it off, the siren is a

standard method for sounding the alarm

over the horn this wire flashes the

lights

it is always connected do not cut this

wire of

once the alarm is prepped tape up your

harness

as we go more into depth on the install

you'll notice that certain vehicles

will need relays or resistors added to

the alarm prep section

once you have learned the added process

you can add that into your prep section

most of the circuits for the alarm are

located at ignition harness

kick panel and below the dash

so order to reach them we will have to

remove the kick panel

and lower section of the dash most kick

panels will be held in by pressure

fitting clips

and that dash is usually held in by bolt

ranging in size

go ahead and remove those panels now

installing the models first helps cut

the install time

first we will start with the LED mount

LED were it can be easily seen from the

outside driver side

a great spot to mount the LED is in a

removable piece a plastic

on the dash use a drill bit to drill a

hole for the LED to fit in

it done correctly LED should be able to

be pressure fit it in

it the whole is slightly too big you can

use a touch of super glue

from behind to seal it in ,the connector

will run through the plastic piece

and plug into the alarm once we have

found a location for it

the programming but should be installed

in a hiddin but assessable location

cover locations include: behind the kick

panel

in the ashtray or a predetermined

location

chosen by the customer the shock sensor

is used to sense

when someone has impacted the vehicle to

install the shock sensor

mount it to a wire harness or fasten it

to inside the kick panel

using self tapping screws mount a siren

inside the engine compartment with the

open and

facing downwards,ground the black wire of the

siren to the chassis ground

most of all circuits we will need to

connect into

are located at the ignition harness, kick

panel

and at the dash so it is only fitting

that the alarm be located close by the

trick is though

is to make the alarm look like it came

from the factory built in

that way theives cannot easily

defeated it

make sure and choose a location for the

alarm they were not cause it to

interfere with moving parts

once you have decided on a location rout

the shock sensor connector

and the LED connector to the alarm then

plug them in

once that is complete mount the alarm brain

using a wire tie zip tie

to bundle wires in a dash or a solid

metal mount

to test the circuit we must use a

multi-meter it is best to use a

multimeter with a negative test Leed

fitted

with the alligator or ground terminal

clip

this helps free up one of your hands for

easier testing

furthermore if you are a frequent alarm

installer you want to purchase a set a

piercing probes

it makes testing alarm circuits

extremely easier

set your meter to the 12 volt DC range or

the closest range to it

ground a negative test Leed to the vehicle

chassis

first thing I look for when testing a

wire

is the molex connector for that wire this

provides the easiest way to test the

circuit

just place your test lead to the

contacts inside

on some circuits that is not possible

because it may be too hard to trace a

circuit back to its molex plug

this is when peircing probes come in

handy, the other option is if you're

using an tap connector

you can connect into the wire with a tap

and then test the T Tapp

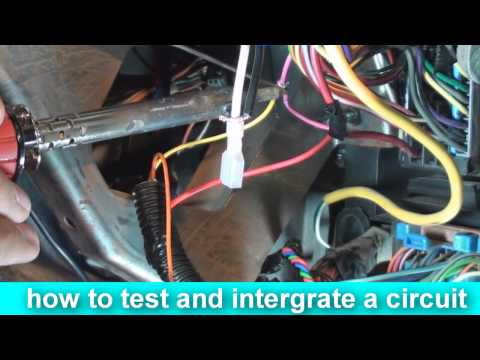

now that we have the general idea on how

to test the wire

let's go ahead integrate into a wire

let's go over various ways to integrate

into a wire

there are various ways connected to a

wire, most common are

connectors such as T Tapp and

integration by Solder

at the two connecting metods I

recommend solder

t taps are a good way to integrate

into a alarm

but any installer will tell you that solder is

the strongest connection possible

so when possible use this method for your

install

to solder you when the soldering flux, a

soldering iron

and some electrical tape preferably the plus 33 type by 3m

to start plug in your soldering iron and

let the heat up for a good 10 minutes

this step is crucial in a good soldering

connection

if you try to solder when a iron is not ready

you end up getting bad solder joints

now I will show you how to solder into

the wire first

you will need to open up the wire, the

easiest way to do this

is to use a wire splitter tool, just insert

a wire

squeeze the handle and it was separate

insulation from the wire

although it is not work very well on

smaller thin gauge wires

another way to open a wire is to use wire

strippers

to do this bite into the insulation with

the stripping section with the strippers

then with some force push the wire

strippers away from you

the insulation should slide off for the

wire

now that you have the wire expose use your pic tool

and pierce the Center of the wire, take your alarm wire and strip back a half an inch

an insert it in between the wire then

wrap it tightly around the circuit

grab your soldering iron and apply heat to

the bottom of the circuit

let it heat the wire up this should take

about a good 10 seconds

then when ready tap the rosin core to

the tip

of the soldering iron it should now

easily then apply the soldered directly

to the top of the circuit

let the solder flow into the circuit

once you are happy with the results

use electrical tape to insulate the exposed

circuit

T taps integrate into the wire by

bitting down

on the circuit when using an T tap it

is very important to you the correct

size tap for the wire gauge your

integrating into

there are three sizes of T taps they are

easily identifiable by the respective

color ,the red tap is used

for smaller wire 22 gauge to 18 gauge

the blue tap is used for medium size

wire 16 gauge to 14 gauge

and the yellow tap is used for thicker

ignition harness wires

such as 12-gauge to 10 gauge to use a T tap

you will need a pair of pliers insert the T tap

onto the wire then clamp down on the

wire you should hear it click

if you don't you need to remove it and try again

once the T tap is in place crimp a male

connector onto wire

that will be inserted in, make sure you

the proper male connector on the alarm

wire

Base it on the gauge of the alarm wire not

the circuit you're interfacing into

the number one reason these connectors

fail is due to using the wrong size

connector on the alarm harness

and used the wrong size t tap

lets locate test integrated circuits for our alarm

bring out your tech notes

multi-meter and connectors we will start

at the top of the text sheet

and make our way down this wire connects

into the vehicle circuit that shows 12

volt

regardless a vehicle key position and

will show 12 volts even when no key is inserted

it is normally found at the ign

harness use your test lead to verify the circuit

once verified integrate into the circuit

this wire connects into the circuit

that shows 12 volts when the key

cylinder is in the on position

which is the second click over and also

shows 12 volts

during the cranking at the vehicle this

wire

is normally found at the ign

harness use your test lead to identify the circuit

once verified integrate into the circuit

when the alarm is armed

this wire sends a negative pulse to the

starer kill relay

when this happens the relay internally

creates a break

of vehicle starter wire resulting in

the vehicle not being able to start

to test the vehicle starter wire contact

the suspected circuit

it was show 12 volts only when the

vehicle is cranking

once this wire is verified cut it then try

to start the car

the vehicle should not start let's look

at the starter kill relay and its harness

as mentioned before this relay will

create a break in the vehicle starter wire

plug the relay into the starer kill

harness, you will notice that the harness

has four wires

two of the wires will go to the vehicle

starter wires one wire will go to the

alarm ground output when armed wire

and the last wire will go to vehicles ign wire

to connect this harness take relay contact 30

and 87a crimp a butt connector on the two

wires

next a contact 30 a connect it to the

starter side

other starter wire then connect 87 a

to the ignition switch side of

starter wire

next crimp a female disconnect connector

onto wire relay contact 86 this

will connect

into the alarms ground output when armed

wire next take the relay contact number 85

and connect it to the vehicle's ignition

wire this wire completes the electrical

circuit

if you haven't done so already crimp a

ground ring

to the ground wire from the alarm

sand off any paint from where you will be

grounding the wire

and drill it into the chassis the vehicle

using a self-tapping screw

when the system is armed and someone

opens the door

the alarm reads that a doors is open and sounds

the alarm

to test the circuit contact the suspect

a circuit with your meter

Press in and depress the door pin it is

usually located

on the door jam when you press it in it

thinks the doors close

when you release a it thinks it doors

open when it opens you should see a

change in voltage

it will either go 12 volts positive or 12

volts negative

depending on the polarity of your door pin

when the alarm is breech

this wire sends a positive output to the

siren causing it to sound

this wire will run through the firewall

into the engine where the siren is located

connect this wire to the positive side

of the siren using a connector, this wire when

connected to a light switch

will flash the parking lights this a circuit

in the vehicle

shows 12 volts when the light switch is

turned to the on position

most vehicles have a positive trigger

light so all alarms from the factory

come with this installed if your vehicle

has a negative triggered headlight switch

then you will need to convert output

of the alarm using a relay

most alarms may have a feature where you

can change output

of the light flash refer to your alarm manual for help

to test the circuit may contact with a

suspected circuit

turn headlight switch on/off your meter

should change voltage to either positive 12 volts

or negative 12 volts, once this wire has been verified

integrate into the circuit, when the lock or the unlock button is pressed on the remote

these wires when connected will send a pulse to your door locks telling them to lock and unlock

normally the output on these wires from

the alarm are negative outputs

check your tech notes to see what polarity your

vehicle door locks need to activate

there are couple different types of door

lock systems

most common are negative pulse and

positive pulse

others include reversed polarity, single

wire

vacuum locks and data control locks if

your vehicle locks

are something other than negative you

will need to prept the door lock outputs

for such door locks

to test a positive or negative door lock

circuit

make contact with the lock wire hit the

lock switch

on the vehicle the circuit should

trigger 12 volts

or 12 both negative depending on the

door lock system

once a circuit is verified

integrate into the circuit ,test the unlock door

circuit

by making contact with the circuit hit

the unlock switch

on the door, it should change voltage just

as before, once a circuit is verified

integrate into the circuit after all

wires had been integrated

test the alarm functions to test the

vehicle close all the doors

but leave the windows open, arm the alarm

and wait 20 seconds for the unit to arm

reach an and open the door through the

window

the siren or horn should sound do this

for each door

if you have the hood and truck monitored

arm the vehicle

and pop the hood release cable from

inside and open the hood

the alarm should go off once the hood

truck and doors are tested arm the vehicle

get in and try to start the car with

the key it should not start

to test the shock sensor hit the base at

the steering wheel

the shock sensor should go off if not

you may need to adjust the gains a

little bit higher

well that wraps it up for the alarm

install video thanks for watching my

video

How to Hot-Wire a Car

Howcast:

How to Change Tie Rods (inner and outer tie rod ends)

ChrisFix:

Hey guys Chris fix here and today I am going to show you how to replace the tie-rod ends

both the outside and the inside tie rod

ends

very important for your steering and for

your toe

alignment so I am going to show you how to do that now, so there is your tie rod

you can see I can move this with my hand, it is very old

300,000 miles will do that to it. It is amazing they made it that far

so here are all of the tools you are going to use for this job. You need

a couple wrenches, screwdrivers, flathead

screwdrivers

some lock tight thread glue

a torque wrench, a breaker bar, hammer,

rubber mallet, needle nose plyers

and a grease gun and the new tie rod

inside and outside. You will also need an inner tie-rod tool

which is this right here. You can rent

this for free Autozone or Pepboys or

whatever the main part stores you use.

So what you are going to do is take your needle nose plyers

and open up the cotter pin so that it is straight.

And once the cotter pin is straight, grab the other side

and start pulling it out.

there we go

one cotter pin pulled out.

Now you can put a 19mm or 3/4 ratchet or wrench on this.

A nice long break a bar will help.

Once you break it loose, use your ratchet

and take the castle nut off.

now there's a tool that you can use that

goes in here and pry's this up, but

what I am going to do is take this castle nut and I'm gonna flip it over

so screw it in this way.

Good! Now I am going to take a hammer, I'll use a rubber mallet just to be safe

and I will pop it up maybe up

[Metallic Hammering Noise]

There we go.

The tie rod end is out. Now this is the

interesting part

there's a nut here that they use for

your alignment

because this affects your alignment.

What you want to do is put your tie rod in and now we can unscrew this nut.

You just want to break that loose like that and now we can take this out and

you can see this spins freely... From the bottom here

that's that the bottom which is pointing down,

you wanna take this

and you want to spin it.

So that is one, two... and you want to count how many spins it takes to get this off.

three, four, five, six...

18, 19... So twenty spins total,

it took me 20 spins you get this off and

when you put the new one on

you want to count twenty spins and the

reason why is it that your alignemnt

isn't completely out of alignment. You are still gonna have to get the car aligned

after you change this

but at least your alignment wont be so bad

that it's dangerous to drive

so you could see this moves around very

easily and has a little bit of play inside and outside

so the inner tie rod end also needs to be changed, but we were going to do that anyway

Now you can see, so the tie rod end works by steering the car when you turn the steering wheel

it turns this which allows the car's

wheel to turn

it goes all the way up into here, and now there is a boot here

and you want to use a pliers to get

this off and there's also

a another one these except you have to break the clamp with a screwdriver,

and I will show you that now.

but that is all the way in the back

so for this one, you just get the

the same needle nose as before

squeeze it and pull it out.

all this is, is a little clamp to keep the boot on.

Now little trick here is to use a

screwdriver a flat head

and just bend this up a little bit. Not

too much because we are re-using the boots

you just want to get it under here so we can spray some silicone or grease

to make it slide off easier

Now we just go in here, with a flathead screwdriver,

carefully, without breaking the boot it's

like that

just like that... You see how the boot is up... get your WD40 or whatever

some type of grease or silicone, which is what I am using

and just spray it in there.

and that will make the boot come off a lot easier because surprisingly, the boot is on there tight.

the next thing we are going to do

you see that clip right down there

there is a clip right there, and what you are going to do is push the screwdriver in and turn the screw driver to open the clip

it's hard to see but I think you will get the idea when I do it.

You just get the screwdriver in there

and turn... [clicks open] and you can see

it opened up, and now we can take the boot off.

[Spray]

OK, unscrew this nut here so we can take the boot off.

take the bolt off, slide off your clamp,

now take your bellows boot off

good, so we're gonna wanna quickly

inspect this to make sure there are no cracks

looks good, so when we're installing

it there is this right here

that's gonna slide over the tube

in there

its going to slide over that tube which connects to the other tie rod on the other side of the car

it allows for venting... so you can see the

tube on the top right and then you could

see the

inside tie rod right there with its ball

joint that is

very loose, so now we're going to take

that out.

so here is the actual tie rod

the inside tie rod

and I just want to show you what is going to happen so that you completely understand this.

so here is your adapter

your adapter is going to fit on here, just like that.

So when you turn the tie rod too, it grabs the end and turns it

otherwise it would be hard to get a wrench

on here. You can do it you just have to see if you have

access. The other thing to remember is

that there's sometimes a pin in this

so you have to take that pin out and that is what I am going to go check for now.

You can see on this tie rod end there is a pin right here and this has to come off

so you take a flat-head screwdriver

you get underneith it, and you pry it out.

you could see I'm just prying this up

If you can't get your screwdriver under here that easy, you could use a hammer and the screwdriver

and just get it to indent a little bit. So you could see

I'm almost ready to just knock this thing out

Knocked it right out. So now we can unscrew this.

Just like I showed you, your adapter piece goes right on top just like that.

take your tie rod tool

slide it in

and then you put your ratchet on there.

Once you break it loose like that

this thing should come right out, and if it is not coming out easily

remember there's that pin in there that needs to come out first

here are the two tie rods side by side

the next thing you are going to do is make sure they are the same size

the new one is a little bit longer

so that is going to affect the toe but

we're getting an alignment anyway so

doesn't matter. Now you can see

I can move this really easily, that is the old one

a single finger can move it around

the new one... I cant even move it

it'll have to be on the car for me to move it. I'm going to get some blue thread lock

this is the removable type

and I am going to put a little inside here

Just like so... Now lets install the new tie rod.

never took the old clamp out

the clamp you have to break, take that out.

here is the pin

it's not really reusable

take our new tie rod

and just tighten it by hand

Once you cannot tighten it by hand anymore,

Once you cannot tighten it by hand anymore,

get your tie rod tool

put it over the tie rod

slide it on

then get your torque wrench,

for my vehicle it says torque to 66 to 74ft-lbs of torque

I am going to torque it to 70ft-lbs

Once you torque it, you are set.

I am under the car and you can see the hole for the pin.

That is where you push the pin in... I put a screwdriver head against the pin

like this... and then I used a hammer to lightly tap it in.

and now it's all the way in.

So remember before I was talking about the clip

that is a sacrificial clip that holds on

the boot that you put your screwdriver in here

and you twist and the clip opens up, well, it is only a one use clip

so either you get a new one, which

they're hard to find,

but one temporary solution is to use

zip-ties

I went to go get a bellows boot kit

to see if it comes with new clips and

and it came with zip ties

so although it sounds kinda cheap, the boot doesn't really move

very much so it's okay to use a zip-tie...

It is not a permanent solution like this metal clip

because a zip tie will eventually get

brittle but until you can find a metal clip

zip ties are a good way to go, and that is what I will use.

You can also use stainless steel hose clamps with the nut that tightens it down

The hose clamps are hard to find that are narrow enough to fit the boot.

so zip ties work nicely in this situation.

Now we are going to put the new boot on.

You see that at the end of my screwdriver?

There is that tube and you want to make sure you push

this into that tube... So I actually tightened up the zip ties

first up on the the boot, now I am going to slide the boot in.

so now you just tighten the zip ties after you push the boot all the way on

good

Now we take our clamp, and bring it up

Put it on just like that and we are done with the boot.

so here is the new tie rod end

we can see the new is nice and sturdy

the old one moves really easily. It comes

with all the accessories

the screw in the top, a pin, and a nut. So

they give you a new nut

but it's kinda small, so I will use the old one because it's thicker.

has more thread on it so it will lock

better.

Just screw that old nut back on...

It took me 20 spins to get this

off so I will put it back on with 20 spins.

It is threaded so we will start counting

1, 2, 3, 4, 5, 6 ,7, 8, 9, 10, 11, 12, 13...

14, 15,

16, 17, 18,

19, 20... OK

20 spins, face it down. Now will tighten

our nut up here.

We want the nut to push against

the new tie rod end.

This will keep it from moving.

I am going to put the grease valve on. Just screw it in by hand first.

Now I will use a 5/16 inch wrench

And just snug it down.

You dont want to tighten this too much.

Just enough, and that is good.

Now we will put this into the knuckle.

Line it up...

push it through...

Get your new castle nut and screw it on.

That is how it should look.

I set the torque to 46ft-lbs

And tighten it until it clicks...

[Click]

when it clicks once, you do it again and

in that statement

[Click]

And then that is tight enough.

we will now take our cotter pin and send it though the hole.

good

Now just bend the cotter pin around the castle nut

Like so

Now we're gonna lube this up

Put the grease gun on there and pump it with grease.

you can see the rubber expanding

and once it expands like that, that means you have enough grease in there

and you just finish the job!

You just changed the inner and outter tie rod ends!

Now go get your car aligned.

If the video was helpful, give it a "thumbs up"

and if you like how to videos, and this was good, then subscribe.

I upload how to videos weekly and it will help you save some money

and fix your own car.

If you want to see other "how to" videos, I will have links in the description.

You can also click on any of the videos on the screen.

Posting Komentar

Posting Komentar